Floating Dock Crane: Key Advantages & Superior Features

1. Unmatched Versatility for Marine Operations

Multi-Crane Collaboration: Designed to allow multiple cranes to work side-by-side on the same vessel, maximizing efficiency in busy ports or shipyards.

Adaptable to Varied Environments: Ideal for ports, shipyards, hydroelectric stations, and other marine construction sites requiring heavy lifting.

2. Advanced Engineering for Optimal Performance

Rotating Column & Slewing System: Features a rotating column connected to a vertical column or a rolling bearing-type slewing device, minimizing the tail swing radius for safer, space-efficient operation.

Compact Gantry Design: Reduces the pier cover surface (ground footprint), enabling installation in tight spaces without compromising stability.

3. Robust Mechanisms for Heavy-Duty Handling

Full-Range Motion Control: Equipped with lifting, slewing, luffing, and traveling mechanisms for precise load positioning.

Tilt-Adjustable Boom: Single or combination booms with pitch flexibility enhance operational range and adaptability.

Integrated Safety Systems: Includes load/moment limiters, rail clamps, and electrical protections to ensure safe, reliable performance.

4. Enhanced Productivity with Custom Add-Ons

Optional Auxiliary Equipment: Supports telescopic funnels, belt conveyors, and grab buckets for efficient handling of bulk materials (e.g., coal, grain).

Driver-Centric Cabin: Ergonomically designed operator’s cab with 360° visibility for seamless control.

5. Certified Quality & Durability

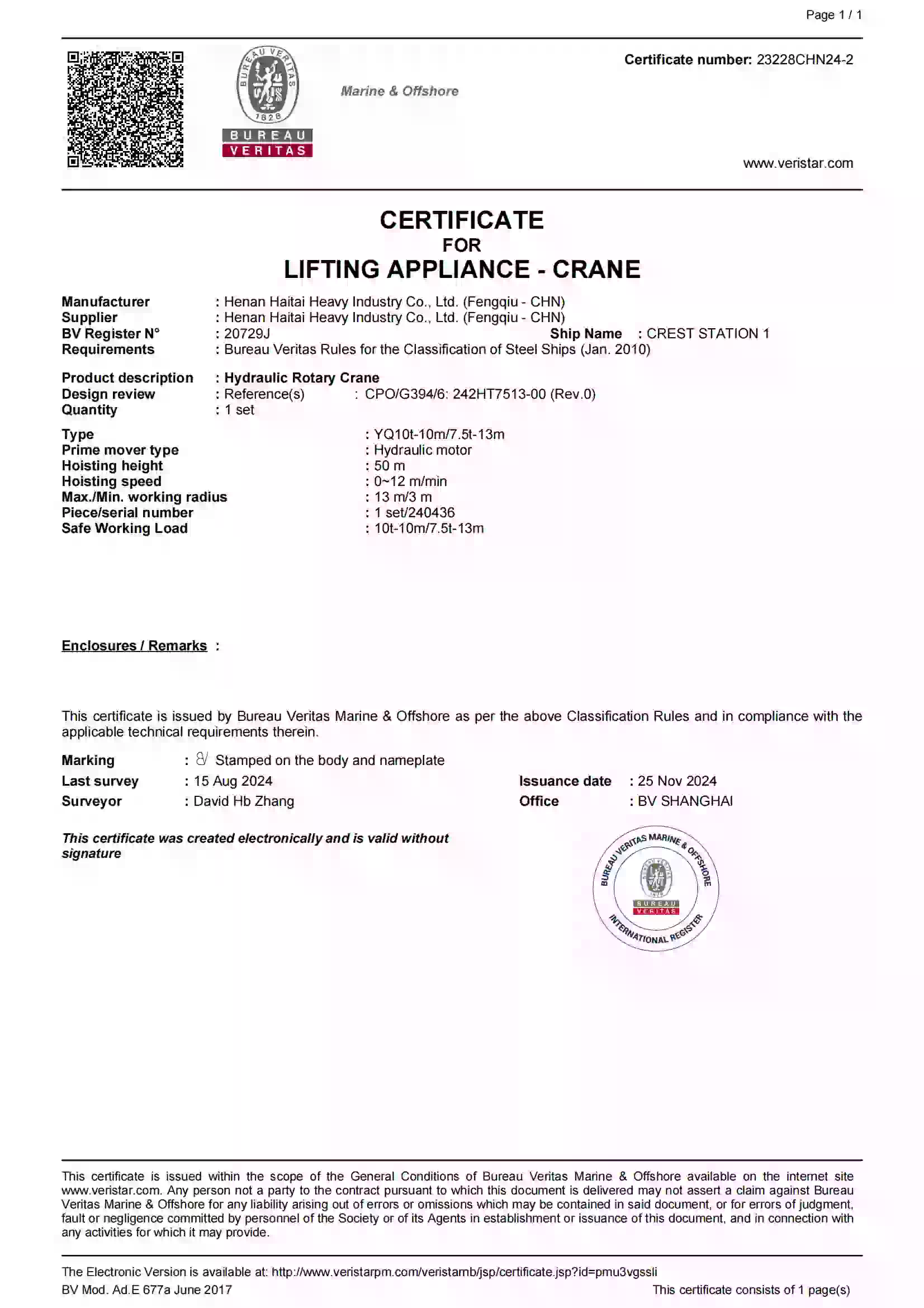

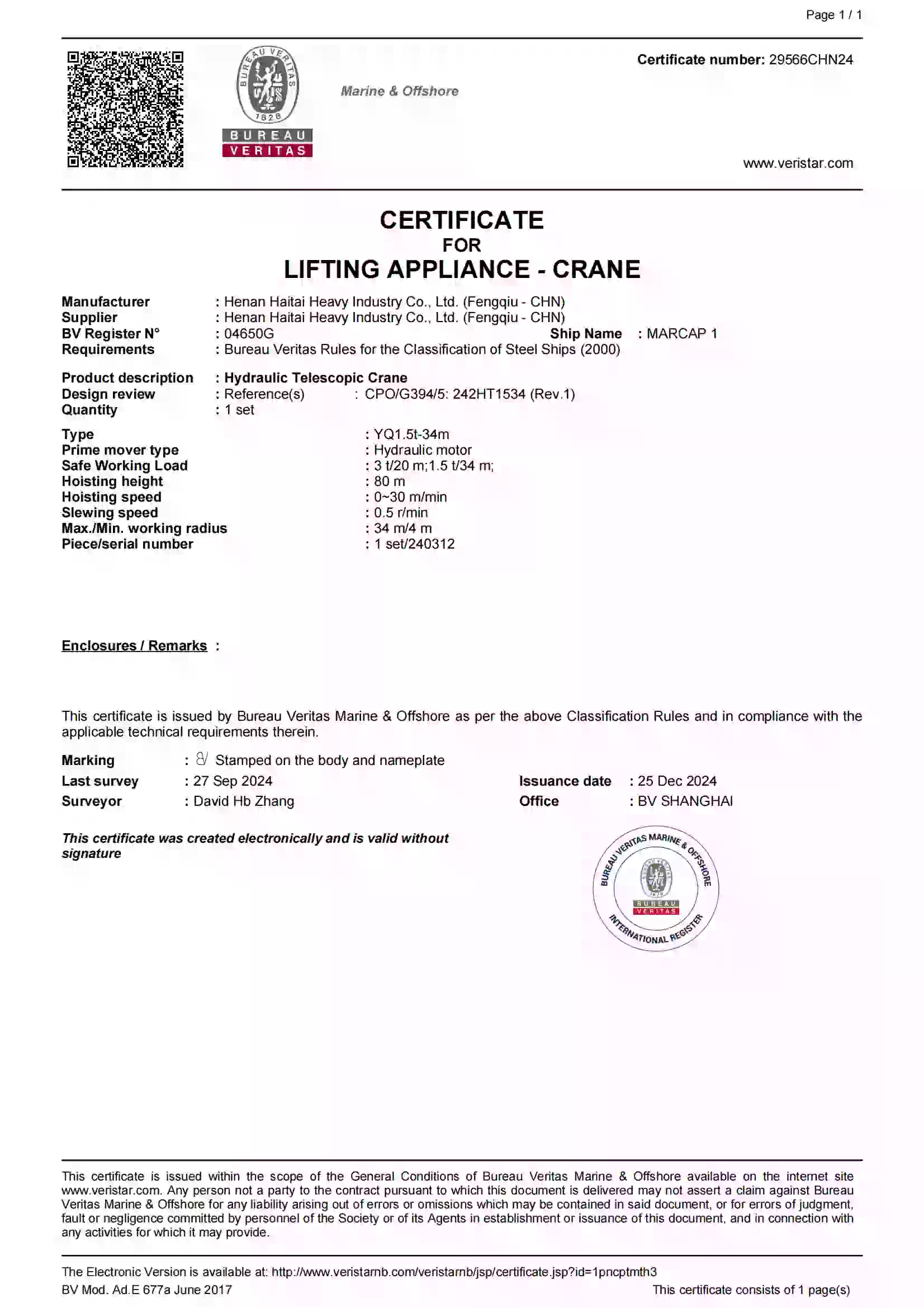

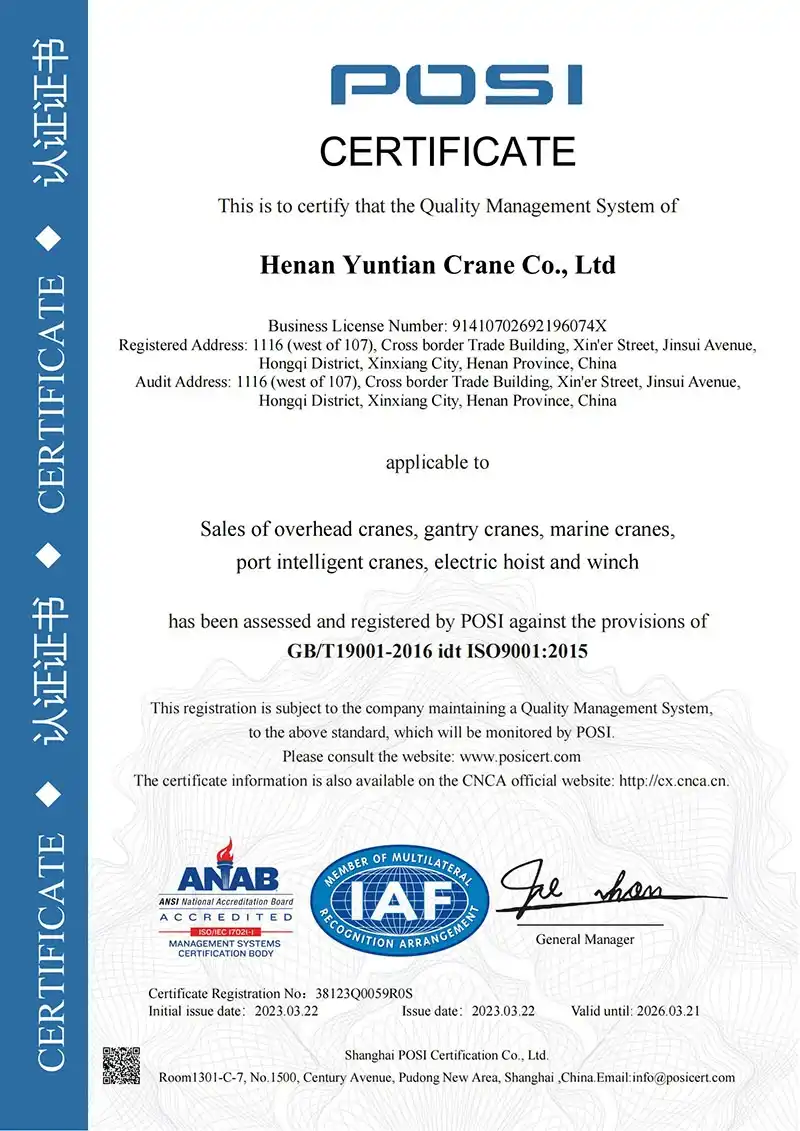

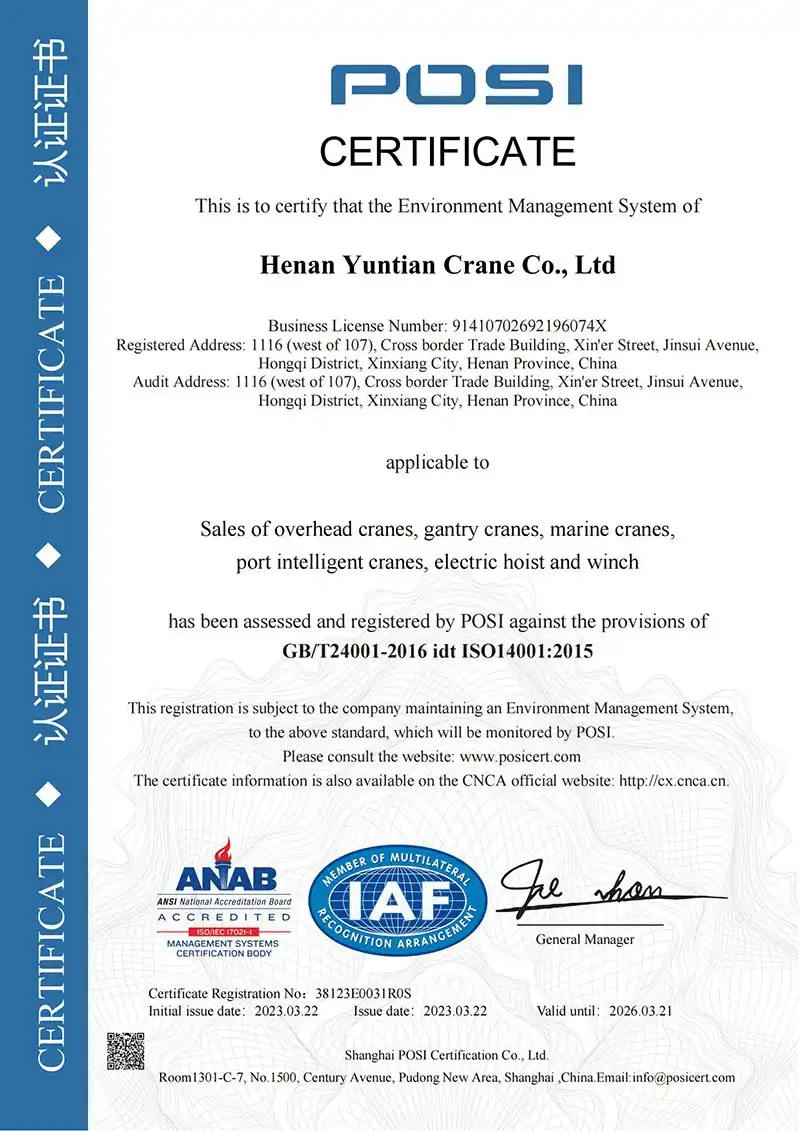

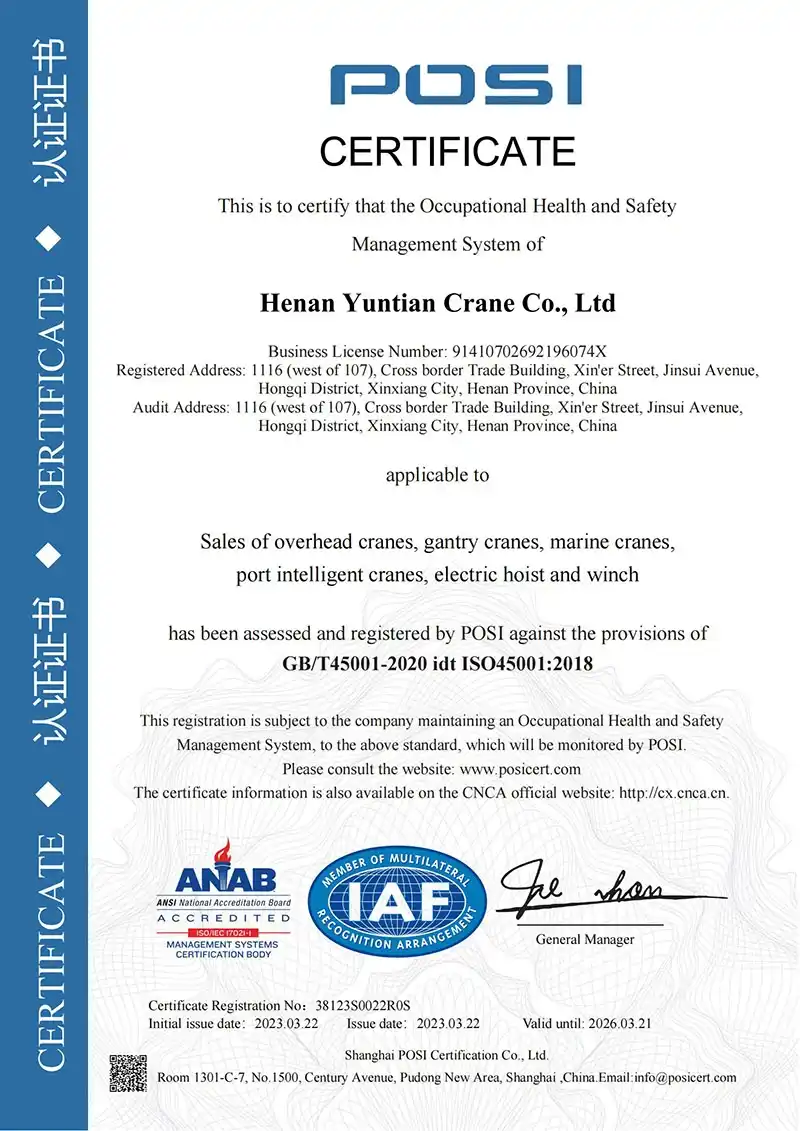

Global Compliance: Manufactured to meet DIN, FEM, IEC, AWS, and GB standards, with CE, ISO, and BV certifications for international acceptance.

Core Component Warranty: 1-year guarantee on critical parts (engine, bearing, gearbox, motor).

6. Customizable for Diverse Applications

Color & Spec Flexibility: Tailored to customer requirements, with lifting speeds of 3–10m/min.

Turnkey Solutions Available: From installation to commissioning, Henan Yuntian Crane provides end-to-end project support.

Why Choose Our Floating Dock Crane?

✅ Space-Saving Design: Minimizes ground footprint while maximizing reach.

✅ High Load Capacity: Engineered for heavy-duty marine and industrial tasks.

✅ Safety & Reliability: Built-in protections and certified components.

✅ Global Trust: Sourced from China’s "Crane Hometown" (covering 2/3 of the domestic market), ensuring cost-effective, premium-quality equipment.

Ideal For: Port logistics, offshore energy projects, shipbuilding, disaster recovery, and inland waterway operations.

Floating Dock Crane: Key Application Scenarios

1. Port & Harbor Operations

Container Handling: Efficiently load/unload shipping containers in congested or shallow waters where fixed cranes can't reach

Bulk Cargo Transfer: Handle loose materials like coal, grain, or ore using grab buckets with optional conveyor systems

Ship Service: Assist in vessel maintenance by lifting engines, propellers, or other heavy components

2. Shipbuilding & Repair

Dry Dock Operations: Install heavy ship sections (hulls, decks) with precision in shipyards

Floating Platform Support: Serve as mobile lifting solution for offshore vessel repairs

Equipment Handling: Move shipbuilding machinery between docks and vessels

3. Offshore Energy Projects

Wind Farm Installation: Position turbine components (nacelles, blades) during offshore construction

Oil Rig Support: Transfer equipment and supplies to drilling platforms

Subsea Operations: Handle pipelines and underwater construction materials

4. Construction & Infrastructure

Bridge Building: Lift and place structural elements for coastal/overwater bridges

Dam Construction: Assist in hydroelectric projects with heavy material handling

Coastal Development: Support pier/dock construction in tidal zones

5. Emergency & Special Operations

Disaster Recovery: Rapid deployment for cargo transfer in flood-damaged ports

Salvage Operations: Assist in wreck removal and marine recovery projects

Military Logistics: Support naval base operations and expeditionary needs

6. Inland Waterway Logistics

River Ports: Enable cargo transfer along rivers lacking permanent crane infrastructure

Barge Operations: Load/unload commodities on inland water transport networks

Lock/Dam Maintenance: Facilitate repair works on waterway systems

Why Our Crane Excels in These Scenarios:

✔ Buoyant Mobility: Works where fixed cranes can't - shallow waters, temporary sites

✔ Heavy-Duty Capacity: Handles everything from containers to wind turbine parts

✔ Quick Deployment: Ready-to-operate solution for urgent projects

✔ All-Weather Reliability: Corrosion-resistant design for harsh marine environments

Featured Models: MQ1025 to MQ4035 series (single boom & four-link boom configurations available)