Advantages & Standout Features of Mobile Harbour Crane

-

Space-Saving Design

The compact gantry structure takes up less space on the pier. This allows several cranes to work next to each other on the same ship. The rotating columns use rolling bearings to reduce tail swing. This helps operations run smoothly even in busy ports. -

Works in Different Ways

It has four main functions: lifting, rotating (360°), luffing, and moving. This makes it easy to handle many types of cargo—like containers and bulk materials—using hooks or grabs. -

Better Efficiency

Extra tools such as telescopic funnels and belt conveyors can be added to handle loose materials faster. Balanced luffing systems and accurate controls help shorten loading and unloading time. -

Works in Many Places

Besides ports, this crane is also used in shipyards and hydropower sites. It is built strong and can work well in different industrial environments. -

Strong Safety Systems

It includes load and moment limiters, rail clamps, and electrical safety devices. It meets the CCS standards (2007 "Ships and Offshore Installations Lifting Equipment Code" and 2010 updates) for safe and reliable operation. -

Easy to Move and Adjust

The gantry base has wheels that allow the crane to change position easily. It fits well in both fixed and changing port layouts, and can be moved quickly when needed. -

Heavy Lifting Ability

Built for lifting heavy loads, it has a strong jib system (single or combined booms) that stays stable even while rotating or luffing. Easy to Use

The driver’s cab is comfortable and user-friendly. Advanced electrical systems like PLC controls make operation simpler and reduce mistakes.

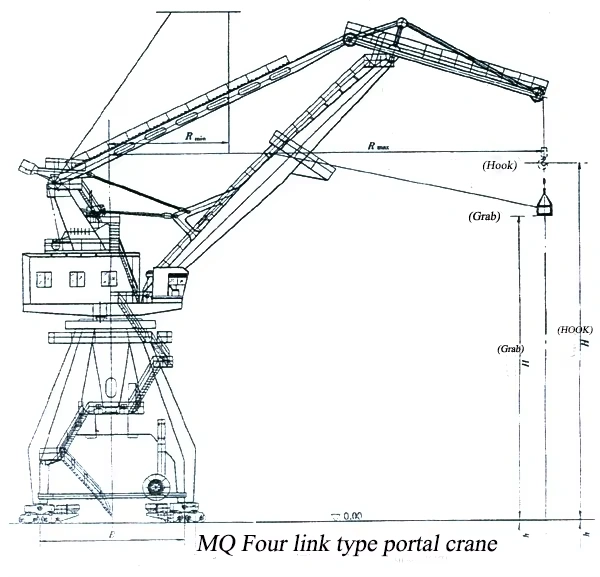

A portal crane is a large type of port handling equipment. Its main structure includes a gate-shaped base and a boom system that can rotate 360°. It works through four main mechanisms: hoisting, luffing, rotating, and travelling. This allows efficient loading and unloading.

Portal cranes are a common type of rail-mounted slewing crane. They look like a gate, so they are also called “gate cranes”. The gate-shaped base runs on ground tracks. Above it, a rotating boom can perform hoisting, slewing, luffing, and travelling motions. Vehicles such as trains or trucks can pass under the gate structure. This makes it possible to load and unload directly between ship and vehicle.

Portal cranes are known for their good appearance, safe operation, advanced performance, easy maintenance, and long service life. They are widely used in port terminals for handling various types of cargo. They are especially common in general-purpose and bulk cargo terminals. In fact, they are one of the most used crane types in many ports.

For example, one port uses 12 portal cranes moving along 700 meters of track. They frequently perform hoisting, luffing, and rotating motions to handle containers. On 8 of these cranes, 5 cameras each are installed for video monitoring. NVR recorders are also used to store video footage.

A custom high-bandwidth wireless communication system by Duobeiton transmits live video to the central control room. Managers can monitor whether operators follow correct procedures, check the status of crane mechanisms, and track loading progress. This supports smart safety management across the port—covering people, vehicles, and equipment.

Port crane operations face complex and changing conditions. Wireless communication can be affected by weather, noise, and electromagnetic interference. The thick metal structure of cranes can also block or weaken wireless signals. It is important to ensure signals can penetrate or go around metal obstacles. In addition, multi-channel monitoring and NVR recording can require up to 80Mbps bandwidth. This demands highly stable and high-capacity wireless communication.

After surveying the working area and distance to the control room, the 8 cranes were divided into four groups. 12 sets of Duobeiton industrial wireless devices were used to build high-bandwidth video links. To support 360° rotation and transmission over 50–350 meters, both omnidirectional and directional antennas were installed. Using point-to-multipoint network mode, video is sent back to fiber nodes. This allows the control room to receive real-time footage from the cranes, upgrading traditional monitoring to smart and visual management.

Duobeiton wireless devices are built for industrial use. They are designed to perform in harsh port conditions. With up to 866Mbps bandwidth, they support smooth transmission of multiple HD videos. High power output (1W) and high-gain antennas strengthen signal coverage. Anti-interference and real-time channel scanning features avoid electromagnetic noise in the port. These features ensure stable video transmission even during rotation and movement of the cranes. This provides strong wireless support for smart port development.

Portal cranes are full-slewing cranes mounted on a gate-shaped frame that moves on ground tracks. They are one of the universal crane types used at quay fronts. Railway cars and road vehicles can pass under the gate. Many bulk terminals in China still use this type of crane.

Portal cranes are relatively fixed in location and can serve various handling tasks between ship and shore, ship and truck, or ship to ship. They are very versatile: they can use a clamshell grab for sand and gravel, a spreader for containers, or a hook for general cargo. Outside China, mobile harbor cranes are gradually replacing portal cranes. However, in some ports, portal cranes are still working reliably.

Application Scenarios of Mobile Harbour Crane

-

Commercial Seaports & Terminals

It loads and unloads containers from ships. This supports high-volume logistics. Its space-saving design lets many cranes work together on one ship. This improves dock output. -

Bulk Cargo Terminals

It moves loose materials like grain, coal, and ore using grabs. Options like telescopic funnels and belt conveyors help move bulk goods faster. It works well in ports that handle large industrial shipments. -

Shipyards

It helps build and repair ships by lifting heavy parts like engines and hull sections. It can also place whole boats. The 360° rotation and luffing allow accurate movement in tight spaces. -

Hydropower Construction Sites

It carries equipment such as turbines and steel structures for building dams or power plants. It is strong and mobile, good for rough areas. It helps meet deadlines in remote or difficult locations. -

Ferry & Coastal Ports

It loads and unloads vehicles, cargo, and luggage onto ferries. Its wheels let it move quickly to fit different ferry sizes and docking spots. -

Emergency Cargo Operations

It helps disaster relief by moving supplies like food and medical gear from ships to land. Its flexible controls and safety systems keep it reliable in urgent situations. -

Industrial Warehousing Near Waterfronts

It moves goods between ships and storage areas. It connects water and land logistics. Its small size saves space. It is good for ports next to industrial zones. Military Ports

It handles military gear, vehicles, and supplies with safe and exact lifting. It follows safety rules for reliable use in important military operations.

A mobile harbor crane (MHC) is a new type of port equipment. It combines features of portal cranes and mobile cranes. It is both flexible and efficient. It is mainly used in the following situations:

General Port Handling

General and container cargo: It can change attachments quickly. It handles steel, wood, machinery, and containers. It rotates and luffs to move goods between ships, yards, and trucks.

-

Bulk cargo support: It helps with cleaning and moving small piles of coal or ore. It works together with dedicated bulk handling machines.

Multi-Purpose Terminal Operations

It handles many types of cargo. It reduces the need for different machines. This improves terminal efficiency.

Yard and Warehouse Handling

It is used in storage yards, logistics parks, or mining areas. It stacks, unpacks, and moves goods short distances. It works well with piles of steel, wood, and containers. Its rotation and luffing cover a large area.

Emergency Response and Special Operations

Salvage work: It is used on salvage ships or shores. It provides stable lifting for sunken ships or objects.

-

Disaster relief: After earthquakes or floods, it lifts heavy parts of broken buildings, clears ruins, or moves relief supplies and equipment.

The mobile harbor crane is flexible and adapts to many conditions. It is especially good for small and medium ports or changing work environments. It is an upgraded replacement for traditional portal cranes.

It performs four main actions: hoisting, rotating, luffing, and moving. It is made for unloading large ships. It handles up to 70% of port tasks.

Key Advantages

Flexible structure: It offers 6 structure types including lever and cylinder gantry. It works steadily in very cold or hot weather. It operates normally in strong wind.

Smart and accurate: It lifts up to 40 meters high with 35 meters reach. It covers the whole ship with 360° rotation. Its anti-sway system speeds up ship unloading by 50%.

-

Multi-functional: It switches between grabs for bulk and spreaders for containers. It handles jobs from loading ore to emergency rescue.

Application Examples

Continuous handling at bulk terminals, precise lifting of large modules in shipyards, and emergency rescue for major projects.

A Mobile Harbor Crane (MHC) is efficient and flexible. It is used in small and medium ports for containers, bulk, and general cargo. It comes in fixed, rail-mounted, and other types.

MHC is widely used overseas. In China, portal cranes are more common. The MHC is an upgraded version of the portal crane.

In short: MHC has features of both portal cranes and mobile cranes.

Good Visibility

The MHC has two cabs. The upper cab is in the middle of the tower. The operator can control hoisting, luffing, rotation, travel, and outriggers. The view is clear. This improves efficiency and safety. The lower cab is on the slewing platform. It is used for moving the crane.High Boom Hinge, Large Work Area

The MHC is a type of jib crane. The boom hinge is in the middle of the tower. This gives a big work area. It increases reach and lifting height. It helps the crane work near ships and cargo piles.Compensation Pulley

The MHC has a compensation pulley at the top of the tower. This keeps the load level during luffing. It saves energy.Dual Power Drive

The MHC can use two power systems. It can use a diesel engine. It can also use shore power. Some models have a small diesel engine for moving. Other actions use shore power. This lowers cost and reduces emissions and noise.Smooth and Reliable Operation

The MHC lifts light loads fast and heavy loads slow. It rotates slower when working at larger radius. Operation is smooth.Good Economy

The MHC weighs only 30%-40% of a similar quay container crane. It costs only 50%-70% of one.