Key Advantages and Features of DPT Shipbuilding Gantry Crane

1. Strong Lifting Capacity and Wide Use

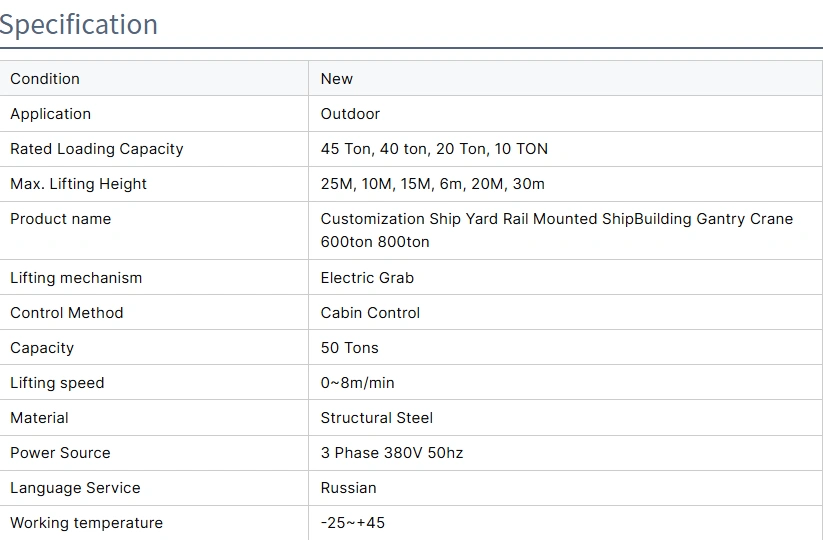

Wide weight range: DPT cranes can lift from 50t+50t to 900t+900t. They handle very heavy ship parts like main hull sections and large steel structures.

Two trolleys that work alone or together: The hooks can be adjusted for lifting odd-shaped items like hull segments. This improves efficiency in complex tasks.

2. Strong and Long-Lasting Structure

Made with strong steel: The main beams use Q345 high-strength steel (yield strength 345Mpa, following GB/T1591-2006). This offers good strength and value for long-term use.

Anti-deformation design: The main beams and flexible legs are connected with spring joints. They expand freely on rubber bearings, which reduces rail wear and lasts longer.

Stable legs: The crane uses both A-frame flexible legs and A/I-frame rigid legs. This keeps the structure stable under heavy loads in shipyards.

3. Efficient and Safe Trolley and Hoist Systems

Precise control: Trolleys use frequency conversion motors (from brands like Jamusi or Dalian) and hardened gear reducers. This allows smooth and accurate movement. Limit switches and buffers avoid over-travel and crashes.

Reliable hoisting: The system uses 18x7 wire ropes (tensile strength 1670Mpa) and drums with diameter ratios over 18. overload and overspeed protection add extra safety.

4. Improved Safety

Full safety systems: Includes rail clearers, rectifying wheels to prevent deviation, and wind-resistant devices (like wheel clamps and anti-wind shoes). These work with anemographs for stable operation near water.

Meets international standards: Complies with CE, ISO 9001, and BV (Bureau Veritas) certifications. This ensures global safety and quality rules are followed.

5. Customization and Flexibility

Made to fit needs: Suitable for small repairs to big ship construction. The split bearing box option makes assembly and maintenance easier, reducing downtime.

Easy integration: Works in shipbuilding docks and dry docks. Supports hull assembly, moving parts, and loading heavy machinery. Fits different workflows in marine manufacturing.

6. Trusted Maker and Support

10+ years of experience: YUNTIAN exports cranes to over 100 countries. Pre-production samples and final inspections ensure consistent quality.

After-sales service: Installation teams and multilingual support (English, Spanish, French, etc.) help with setup and long-term maintenance.

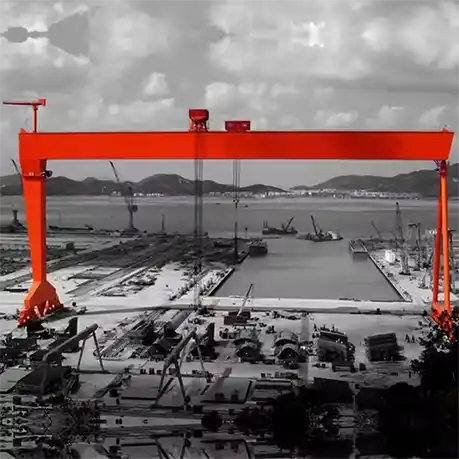

About Shipbuilding Gantry Cranes

Shipbuilding gantry cranes are made to lift very heavy loads over large spans and heights. They are mainly used for turning and assembling ship sections in mid-air.

These cranes usually have two trolleys—upper and lower. Each trolley runs on its own track, and the lower one can pass under the upper one. By coordinating the hooks and movement of both trolleys, the crane can easily turn large ship segments.

They are used in shipyards, dry docks, or platforms for lifting and turning ship sections. Their main features are high lifting capacity, wide span, and great height. They can lift from 100t up to 2500t, span over 40m (up to 230m), and reach 40–100m under the main beam.

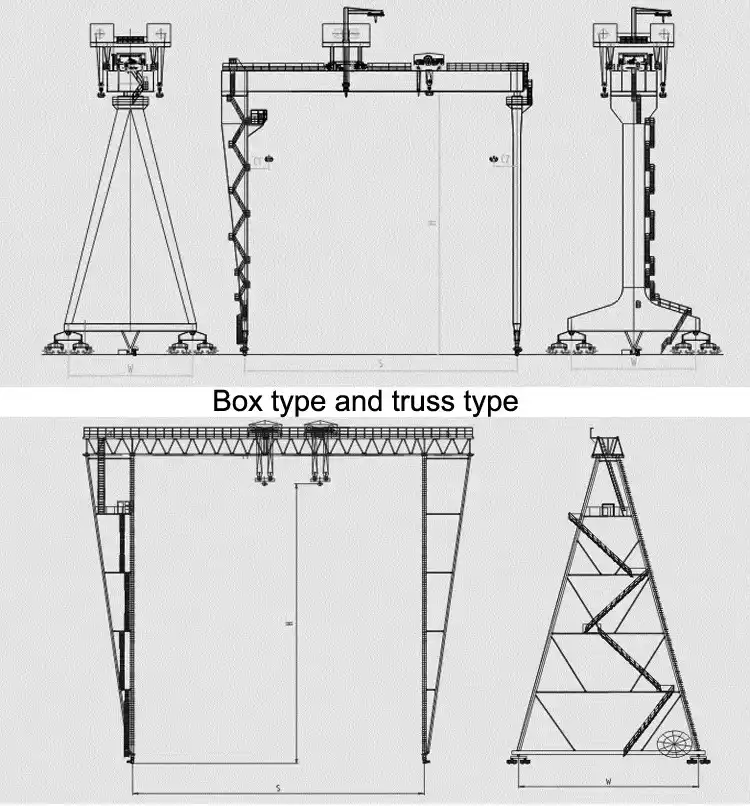

Because of their wide span, these cranes often use one rigid leg and one flexible leg. The rigid leg is fixed to the main beam, while the flexible leg is connected with a flexible hinge. The main beam can be single or double.

To meet shipbuilding needs, these cranes can perform single lifting, dual-hook lifting, triple-hook lifting, mid-air turning, and fine rotation. They are especially useful for turning and assembling ship sections.

Most shipbuilding cranes have two trolleys. The upper trolley has two lifting units with the same capacity. The hooks are located outside the main beam. They can work together or separately for turning or rotating segments. The lower trolley has a main and an auxiliary hook. The main hook can work alone or with the upper trolley’s hooks for triple-hook lifting or turning. The auxiliary hook is used for smaller loads.

Henan Kuangshan recently built a 450t large-span shipbuilding gantry crane now in use. It is used for moving large ship and offshore segments. It combines lifting, moving, turning, and assembly functions. It allows efficient, precise, and safe movement and installation of ship parts. It is key to improving efficiency in shipbuilding.

The main beam is trapezoidal. Legs are I-shaped rigid and A-shaped flexible. Operators and maintenance staff can use stairs or an elevator inside the rigid leg to reach the cab and main beam.

The lifting system has a rope arrangement device to prevent rope jumping and improve safety.

The travel system includes a skew correction device. It can automatically or manually correct travel deviation.

Uses smart control with multi-hook coordination and sync movement. With PLC and frequency control, it allows millimeter-level precision.

Includes safety monitoring, anti-collision system, wind protection, fire alarm, and other safety devices.

This crane is a heavyweight helper for shipyards. Its rigid-flexible leg design and dual-trolley coordination allow precise lifting of large ship segments and heavy modules. It makes assembling giant ships steady and safe.

Product Highlights

Steady and strong structure: Combines rigid and flexible legs with single or double main beams. Lifts 50–1000 tons with precision.

Dual trolley coordination: Upper and lower trolleys work independently. The lower one can pass under the upper one, improving assembly efficiency by 50% and shortening timelines by 20%.

Multiple lifting modes: Supports single-hook, dual-hook, and triple-hook lifting. Suitable for ship plates, thrusters, cabin modules, and other unusual parts.

Suitable for: Coal/ore yards, steel rolling mills, and new energy equipment manufacturing bases.

Shipbuilding Gantry Cranes: Applications and Features

Main Applications

Ship Hull Construction Yards: Lift and position large steel plates, hull sections, and other parts. Ensures precise alignment during ship assembly.

Offshore Platform Manufacturing Facilities: Handles heavy modules like deck sections and equipment skids. Used in building oil rigs and drilling platforms.

Marine Repair and Maintenance Docks: Lifts damaged ship parts, engines, or propellers. Helps perform efficient repair work on vessels.

Naval Shipyards: Used in constructing military ships like warships and aircraft carriers. Provides high-precision lifting of weapons and special components.

Container Ship Construction Sites: Installs container cranes, hatch covers, and cargo systems onto ships. Supports loading equipment integration.

Cruise Ship Manufacturing Plants: Lifts luxury interior modules such as cabins and dining areas into place during cruise ship outfitting.

Ship Launching Areas: Moves finished ships from dry docks to water. Transfers vessels safely onto launch platforms.

Heavy Machinery Loading Terminals: Loads large engines, generators, and propulsion systems onto ships. Ensures safe and efficient placement.

Shipbreaking Yards: Dismantles old ships. Lifts and removes reusable steel structures and machinery for recycling.

Coastal Ship Repair Basins: Lifts and replaces heavy parts like rudders and propellers. Supports maintenance for commercial and military ships.

About Shipbuilding Gantry Cranes

Shipyards, floating docks, and loading terminals often need to lift and repair ship sections. These tasks require high lifting capacity, wide span, and great height.

To meet these needs, we developed the DPT Shipbuilding Gantry Crane. It offers high lifting capacity, wide span, great height, multiple functions, and a stable structure.

Six Key Features

Multiple Functions

The crane can lift single or multiple loads, turn objects in mid-air, and make small horizontal rotations. It handles different lifting situations and improves work efficiency.Gantry Design

Users can choose single or double girder types. The main girder uses variable cross-section design. This improves strength and stability for safer lifting.-

Leg Design

Users can choose single-column rigid legs. This design offers better support and stability for safe crane operation. Lower Trolley Design

The lower trolley has a main and an auxiliary hook under the main girder. This allows multiple lifting points and increases flexibility.Crossing Operation

The upper and lower trolleys can cross under each other. This improves flexibility, saves time and labor, and increases efficiency.Frequency Control

All lifting and travel mechanisms use frequency speed control. This allows adjustable speed, more precise control, smoother movement, and energy savings.

Key Characteristics of Shipbuilding Gantry Cranes

Wide Span and High Lifting: Designed for shipyards, dry docks, and platforms. Handles complex lifting tasks with high capacity, wide span, and great height.

Multiple Functions: Supports single and dual hook lifting. Meets various needs such as turning and moving ship sections. Handles different lifting modes with efficiency.

Strong and Safe Structure: Uses single or double girder design. Main girder uses optimized variable cross-section for better rigidity and stability. Lifting and travel mechanisms use frequency control for precise speed adjustment, smooth operation, and safety.

Smart Control for High Efficiency: Uses digital control systems. Monitors operation status and adjusts settings in real time. Improves safety and efficiency. The crossing feature between upper and lower trolleys increases flexibility in complex environments.

Shipbuilding gantry cranes are widely used in shipbuilding, military aerospace, new energy, and other fields.