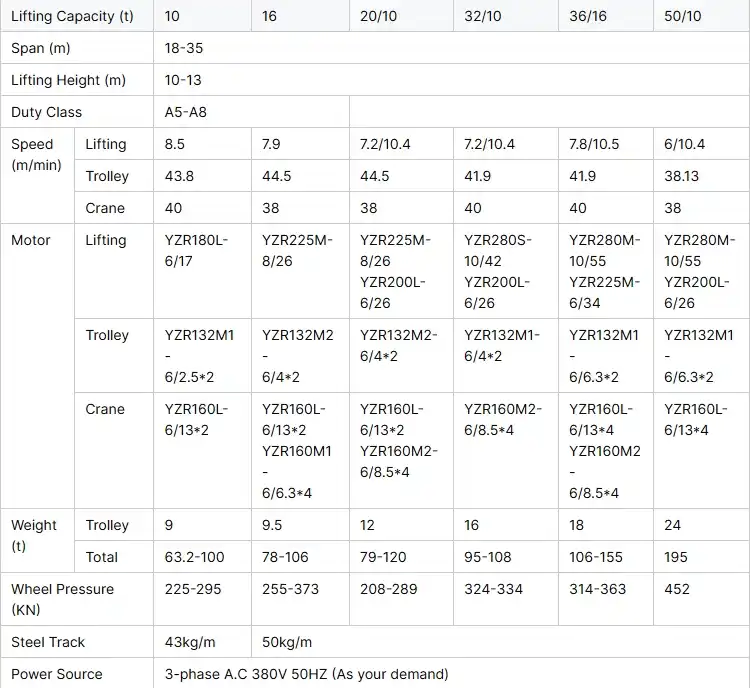

Straddle Carrier: Advantages and Key Features

1. Strong Structure Design

Robust Main Beam: The U-frame is made as one solid piece without welding. Full-beam welding is used for high precision. This gives strong vertical and horizontal stiffness. It lowers the machine’s own weight, reduces wheel load, and improves stability.

Improved End Carriage: Uses a motor-reducer-wheel drive and soft-start motor. This allows smooth and steady movement, which reduces part wear.

Heat Resistant: A special heat-protection coating is applied under the main beam. This increases heat resistance and extends service life in high-temperature conditions.

2. High Performance and Efficiency

Long-Lasting and Efficient: Built for heavy, long-term use with very little downtime. It keeps working steadily in busy logistics areas.

Smooth and Reliable Operation: Starts and stops smoothly. The winch trolley runs quietly and does not gnaw the rail. This ensures stable performance and fewer breakdowns.

3. High-Quality Parts and Safety Systems

Top Electrical Parts: Uses Siemens or Schneider electric systems. Includes inverter, PLC, and fault monitoring (CMMS) for accurate control and real-time problem detection.

Safe Tires and Spreader: High-quality rubber tires resist abrasion and have protection devices for flexible turning. The spreader uses four-leg wire rope slings to safely lock 20ft, 40ft, and 45ft containers.

4. Flexible Use and Customization

Adaptable Design: Used for moving, stacking, and transporting containers in ports, terminals, and distribution centers. It works well even in complex conditions.

Custom Solutions: Can provide non-standard spreaders based on customer needs for greater flexibility.

5. Easy to Use and Low Maintenance

Comfortable Cabin: Offers a full view, air conditioning, and user-friendly controls. This helps the operator work efficiently during long shifts.

Long Life with Little Maintenance: Made to last long with minimal upkeep, reducing overall costs.

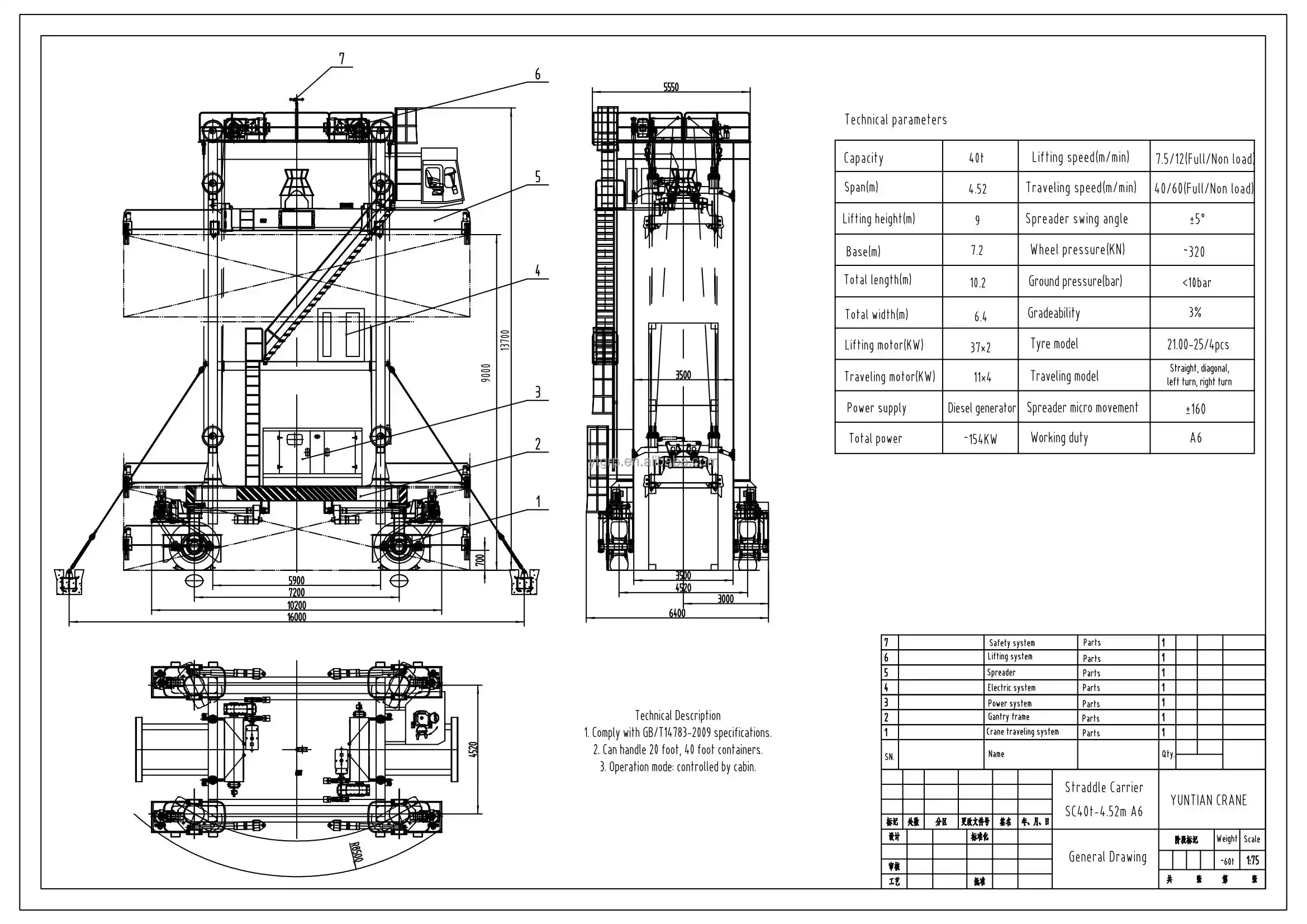

The straddle carrier is a main type of container handling equipment. It is often used for transport between the dock and the yard, and for stacking containers. Because it is flexible, efficient, stable, and has low wheel pressure, it is widely used. Straddle carriers help improve loading and unloading efficiency at docks. Since they were first introduced in the 1960s, they have developed over decades. Like rubber-tired gantry cranes, they are now key equipment in container terminals and yards. Straddle carriers are special machines for moving and stacking containers in docks and yards.

Function

It uses a portal frame that straddles the container. A hydraulic lifting system with a spreader lifts the container for moving and stacking up to 2–3 layers high. A straddle carrier-based system is one of the fastest and most reliable options for medium-sized terminals. The straddle carrier can work as a standalone system. It meets all different cargo handling needs in the container yard: moving and stacking containers, and loading/unloading trucks and rail cars.

Structure Types

There are three main types of straddle carriers:

Without platform, shared structure for moving and lifting.

With platform, shared structure for moving and lifting.

With platform, dedicated structure for moving and lifting.

Most models today use one of these types.

Development Trends

-

Larger Size and Higher Stacking: As containers get bigger and heavier, straddle carriers are also made with more load capacity and higher stacking height. About 70% of existing straddle carriers can stack 3 high, and more models can now stack 4 high. Since extra-tall containers are more common, lifting height has also increased. In the 1980s, the lifting capacity was usually 30–35 tons. Now, most new models can lift 40 tons, and some even 50 tons. Straddle carriers that stack 4 high have greatly improved market competition. Going from 2 to 3 layers increases storage capacity by 50%.

-

Diverse Structural Designs: Thanks to better technology in straddle carriers and hydraulics, there are now more design types. Single-engine models are still common. The engine is placed on top, which is easy for control and maintenance, but raises the center of gravity. For some types, a high center of gravity affects driving safety. Dual-engine models place engines on both sides lower down, which improves stability but makes control and maintenance harder. Besides traditional mechanical and hydraulic transmission, electric transmission is becoming more common.

-

Higher Automation: Almost all straddle carriers now use programmable logic controllers (PLCs) to monitor and control different parameters and functions. With PLC networks, the straddle carrier can connect easily with automated systems, making it easier for the operator. With strong R&D, hybrid diesel-electric, LNG hybrid, and hydrogen fuel cell hybrid straddle carriers have been developed. These are well accepted in the market and are now exported worldwide as products of "Smart Manufacturing in China".

The first new-generation intelligent straddle carrier has been launched and is in dynamic testing. It is the world’s first straddle carrier with an unmanned navigation system, combining artificial intelligence with port automation. By the end of the same year, a new unmanned straddle carrier was officially released. Eight self-developed intelligent straddle carriers were delivered to customers. This product includes multiple independent innovations and has received more than ten patents. Its navigation and control accuracy are among the best in the world. The fleet management software uses a new lifting system that is simple, compact, reliable, lightweight, low-cost, easy to maintain, and good-looking.

A lightweight one-over-three straddle carrier project was delivered. It breaks through traditional design by using a new water-cooled frequency control system and water-cooled hoisting motor, saving space. It set a record for the shortest manufacturing time and most units delivered.

A green energy straddle carrier attracted attention in Busan. It can reduce dust emissions by 99% and greatly cut nitrogen oxides, non-methane hydrocarbons, and carbon monoxide. It uses over 50% less fuel, is highly economical, and fills a gap in the global market for green energy straddle carriers.

A one-over-one hybrid straddle carrier has been upgraded from a diesel-lithium battery mix to a hydrogen fuel cell and lithium battery system. This achieves true zero carbon emissions.

The first straddle carrier project using entirely domestic parts includes "blind spot monitoring" for better safety. It also has a data collection system that greatly reduces maintenance costs. The project uses independent steering control and dual water-cooled drive control. Its mature hybrid technology meets Euro V emission standards. It has adaptive anti-tip and stability control. The smart cabin provides a more comfortable working environment.

A full-electric straddle carrier supports fully automatic charging and can run for 8 hours. The upper platform was redesigned. While keeping the same lifting height, the overall height was reduced by 1 meter, overcoming height limits. It is the first to use all-liquid-cooled drive. The drives are distributed near the drive devices, saving power cables.

Straddle Carrier: Application Scenarios

1. Port Terminals

Straddle carriers are key equipment in seaport operations. They move and stack containers very well. They move containers between ships, storage yards, and trucks quickly. This keeps cargo moving smoothly in busy ports. They handle 20ft, 40ft, and 45ft containers. Their stable starting and precise movement help meet tight shipping schedules.

2. Container Yards

In large container storage yards, straddle carriers are important for stacking. They have strong structure and high lifting capacity. They stack containers neatly to use vertical space well. The heat-protective coating on the main beam lets them work reliably even in very hot or cold outdoor yards.

3. Distribution Centers

Distribution centers that handle many types of cargo use straddle carriers for their flexibility. They move easily between different storage areas. They adapt to different layouts and cargo types, not only standard containers. Their low noise and soft-start motor avoid disruption in busy hubs. The fault monitoring system (CMMS) also reduces downtime.

4. Intermodal Transport Hubs

In hubs where goods move between ships, trains, and trucks, straddle carriers make operations efficient. They turn flexibly because of high-quality rubber tires. They move well in tight spaces. This helps connect different transport modes for fast and safe cargo transfer.

5. Heavy-Duty Logistics Operations

Industries that need heavy container transport over short or medium distances use straddle carriers. They combine the efficiency of a yard bridge and the mobility of a truck. They perform well under heavy use and carry high loads. They are used in manufacturing plants and industrial parks where steady productivity is important.

The straddle carrier is heavy-duty equipment that can grab, move, and stack materials. It has excellent load capacity (30-100 tons), very good space adaptability (minimum 5m turning radius), and smart operation features. It is now essential in modern logistics and industrial systems. Its main advantage is replacing multiple traditional machines with one-machine “end-to-end” operation. This is especially useful where space is limited and logistics speed is critical. It is changing how material handling works in many industries.

Key Equipment in Port Logistics

Ports and container terminals are the most common places to use straddle carriers. With their straddling design, they can pick up containers directly from ships or trucks. They move easily around storage yards and stack containers 4-5 levels high. Compared to traditional forklifts that stack only up to 3 levels, this improves vertical space use by 67% and greatly increases storage density.

Examples:

Shanghai Yangshan Automated Terminal: Uses unmanned straddle carriers with lidar and 5G positioning. They move containers from cranes to the yard with no human help. They handle over 35 containers per hour, much faster than traditional equipment.

Xi'an International Gateway: Uses 12 straddle carriers working together. They handle 3000 standard containers daily and cut cargo turnover time by over 20%.

Efficiency Engine in Industrial Production

In industrial settings, straddle carriers offer precise positioning (centimeter-level accuracy) and heavy-load ability. They work like “mobile robotic arms” on the production line:

Automotive Manufacturing: Tesla’s Shanghai Gigafactory uses custom straddle carriers to deliver battery modules directly to assembly stations. This removes intermediate storage and improves production rhythm by 15%.

Chemical and Heavy Machinery: Explosion-proof straddle carriers have anti-static design and remote control. They move dangerous goods containers safely and reduce risks for workers.

Workshop Internal Logistics: With four-corner support and custom spreaders, they handle special goods like wind turbine towers, tanks, wide containers, and even frozen containers. This improves flow efficiency inside workshops.

Heavy-Duty Tool for Energy and Construction

In energy and construction, straddle carriers perform well even in complex environments:

New Energy Projects: Carry large parts like blades and towers at wind and solar power sites. Their four-wheel steering improves mountain passability by 40% compared to traditional trailers.

Energy Storage Power Station Construction: Hydraulic leveling systems ensure precise placement of storage containers on bases. This keeps cable connections stable.

Bridge Construction: Transport prefabricated bridge sections weighing up to 100 tons. They work with cranes to significantly shorten construction time.

Efficiency Hub in Freight Terminals and Logistics Parks

Large freight hubs and modern logistics parks are new important applications for straddle carriers. Their value lies in breaking down barriers between transport modes, cutting transfer time, and maximizing space use:

Road-Rail Transfer: At railway container stations, straddle carriers can grab containers directly from trains and place them accurately on waiting trucks, or do the reverse. This removes the need for cranes and truck relays. Transfer time per container is shortened to 5-8 minutes (50% faster than traditional methods), greatly improving train turnaround efficiency.

High-Density Yard Storage: Land costs are high in logistics parks. Straddle carriers’ ability to stack 4-5 levels increases storage capacity per unit area by over 60%, easing land pressure.

Dynamic Buffer Management: In distribution centers, straddle carriers act as “mobile shelves”. Based on order waves, they quickly move containers waiting for sorting from high-density storage to buffer locations near docks. This shortens picking paths by 30% and increases sorting efficiency.

-

Special Cargo Handling: With special spreaders, they safely move refrigerated containers (without breaking the cold chain), open-top containers, and frame containers. This meets diverse cargo handling needs in parks.