Abstract

Marine stiff boom cranes represent a cornerstone of modern offshore and maritime operations, engineered to meet the unique challenges of the marine environment. Unlike their land-based counterparts, these cranes must contend with dynamic wave loads, corrosive seawater, and stringent space limitations on vessel decks. This research article provides a comprehensive examination of marine stiff boom cranes, detailing their design fundamentals, critical technologies like active heave compensation (AHC), structural innovations for enhanced rigidity, and their diverse applications in offshore wind, oil & gas, and cargo handling. The discussion extends to current market offerings, analyzes key engineering challenges, and explores future trends toward greater intelligence and automation, offering a holistic resource for maritime engineers, equipment specifiers, and industry stakeholders.

Introduction and Defining Characteristics

A Marine Stiff Boom Crane is a type of deck-mounted lifting equipment characterized by a rigid, non-articulating boom, designed primarily for the demanding conditions of the marine environment. Its core function is to safely and efficiently transfer cargo, equipment, and supplies between vessels (ship-to-ship) or from a vessel to a fixed offshore structure (ship-to-platform) and vice-vers

The fundamental distinction from land cranes lies in its operating environment. The constant motion of the sea—rolling, pitching, and heaving—introduces dynamic forces that are negligible in terrestrial applications. Therefore, the design philosophy extends beyond simple load-lifting to encompass motion compensation, structural integrity under multi-axis loading, and exceptional corrosion resistance.

To visualize the core design challenges addressed by marine stiff boom cranes, the following table contrasts their key requirements with those of standard land-based cranes:

| Feature |

Marine Stiff Boom Crane | Standard Land-Based Crane |

Primary Environmental Challenge |

Dynamic wave & vessel motion | Static or wind loads |

| Core Stability Mechanism | Ship's deck connection | Ground outriggers / stable foundation |

| Critical Technology | active heave compensation | Load moment indicator (LMI) |

| Structural Focus | High rigidity, fatigue resistance | High strength, maximum reach |

| Space Constraints | Extremely limited deck space | Generally less restrictive |

Corrosion Protection |

Heavy-duty | Standard industrial |

Core Technologies and Engineering Innovations

The operational viability of marine cranes hinges on several advanced technologies that mitigate the inherent instability of the marine environment.

1.Motion Compensation Systems

This is the most critical subsystem, ensuring the load can be positioned safely despite vessel movement.

Active Heave Compensation (AHC): This is a closed-loop system that actively controls the crane's winch. It uses a Motion Reference Unit (MRU) to measure the vessel's real-time vertical (heave) displacement. The control system (typically a PLC) calculates the required winch speed to counteract this motion, effectively "decoupling" the load from the ship's movement. This allows for precise, safe operations in significant wave heights and is essential for offshore construction and deep-water lifts.

Constant Tension Mode: A simpler, often passive system that maintains a pre-set tension on the hoist wire. This prevents slack rope during vessel heave-down and minimizes snap loads, useful for steady-state operations like hose handling.

2.Structural Design for Rigidity and Compactness

The boom structure must be incredibly stiff yet lightweight to maximize capacity while minimizing the crane's footprint.

Telescopic Boom Design: To save crucial deck space, most marine cranes use multi-section telescopic booms. A key innovation in this area addresses the traditional weakness of the cantilevered pulley head on the hydraulic cylinder. Advanced designs integrate a guide location device with rollers and lateral cushion blocks, transforming the support into a stable two-point beam structure. This drastically reduces deformation and protects the boom structure from damage during extension/retraction under heavy side loads.

Compact Footprint: Leading manufacturers design cranes with minimal "tail swing," the area behind the crane's slewing ring required for rotation. For instance, Liebherr's CBO series boasts a tail swing radius of less than 4 meters, allowing installation on cramped deck spaces without interfering with other structures or containers.

3.Drive, Control, and Safety Systems

Power Systems: Predominantly electro-hydraulic, offering a high power-to-weight ratio and robust control. Electric drive systems are also prevalent, especially where power is readily available from the vessel's system.

Integrated Safety: Modern systems include Overload Protection Systems (MOPS/AOPS) to prevent hazardous operations, remote control capability for operator safety and better visibility, and often zone protection to automatically limit boom movement in risky areas.

Applications and Market Specifications

Marine stiff boom cranes are versatile tools deployed across the maritime industry.

Offshore Support & Construction: This is the primary domain, involving the transport of supplies to oil & gas platforms, offshore wind farm installation (turbine components, foundation piles), and subsea equipment handling. Cranes for this sector feature high capacities (e.g., 50t to over 100t) and sophisticated AHC.

General Cargo & Container Handling: On supply vessels, multi-purpose vessels, and smaller cargo ships, these cranes handle cargo, containers, and provisions. Capacities typically range from 1 to 50 tons.

Specialized Operations: This includes hose handling for liquid transfer, cable laying, and launch/recovery of smaller boats and remotely operated vehicles (ROVs).

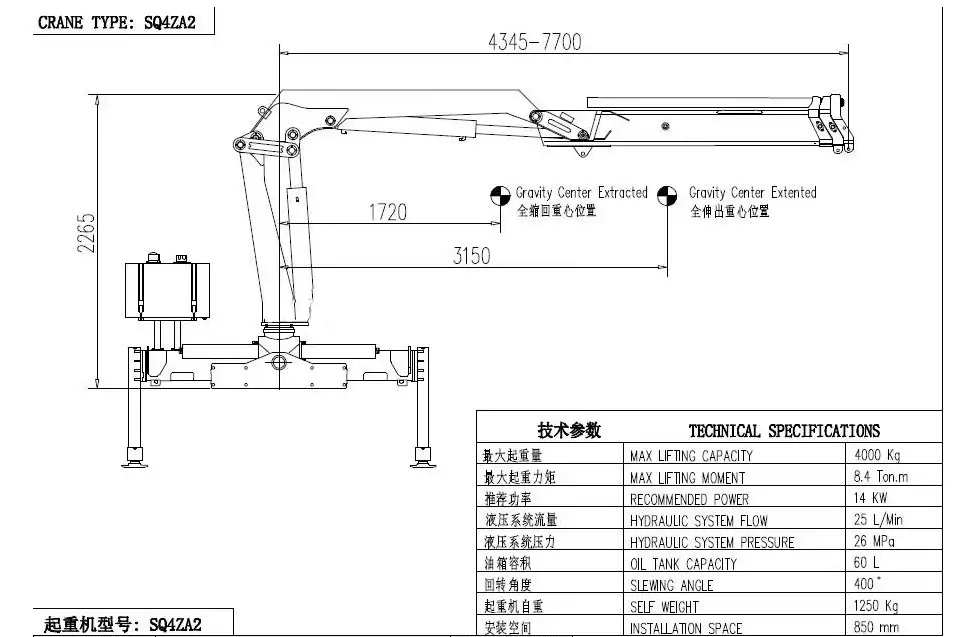

Market Examples & Capabilities:

YMV Crane & Winch Systems: Offers stiff boom cranes with capacities from 1 to 50 tonnes and boom lengths from 5 to 32 meters, equipped with options like AHC, remote control, and constant tension mode.

Liebherr CBO Series: A high-capacity range designed for severe offshore duties. The CBO 3600 model offers a maximum hoist capacity of 100 tonnes and a maximum boom length of 63 meters, with a design focused on maximum stability and a compact footprint.

Research Frontiers and Future Outlook

Current research and development are pushing the boundaries of performance, safety, and autonomy.

Advanced Dynamics & Simulation: Engineers use virtual prototyping tools (like ADAMS) coupled with computational fluid dynamics (CFD) to simulate vessel motion in waves and analyze the complex dynamic response of the entire crane system. This allows for optimizing design before physical build.

Energy-Efficient Compensation: Research is focused on developing high-precision, low-energy-consumption wave compensation hydraulic systems. These systems aim to provide the same level of load stability while reducing the significant power draw of traditional AHC systems, a critical factor for vessel fuel economy.

Digitalization & Intelligence: The future points toward "smart cranes" integrated with the vessel's digital ecosystem. Predictive maintenance based on sensor data, augmented reality (AR) overlays for operator guidance, and fully automated lift sequencing are key areas of development.

Conclusion

Marine stiff boom cranes are highly engineered solutions that transform a floating, unstable platform into a capable and safe lifting base. Their value is defined not just by lifting capacity, but by their integrated systems—advanced motion compensation, ultra-rigid yet compact structures, and fail-safe controls—that collectively overcome the ocean's challenges. As offshore activities expand into deeper waters and more complex projects like large-scale wind farms, the evolution of these cranes will continue toward greater intelligence, energy efficiency, and autonomous operation, solidifying their role as indispensable assets in global maritime infrastructure and energy sectors.

HI! Partner

Henan Yuntian, as a contemporary manufacturing leader, has consistently focused on cutting-edge technology and development in the lifting equipment industry. We invite you to get in touch for professional services including customized crane selection, accurate pricing, and technical design drawings tailored to your needs.

GET A QUOTE

https://yuntiancrane.com/

sales@sgycranes.com

Phone:

+86-373-3055523

+86-17337353108