What are Offshore cranes?

Offshore cranes, specialized lifting systems mounted on vessels or platforms, are the indispensable workhorses of maritime and offshore industries. Unlike their land-based counterparts, these cranes operate on a dynamic, moving base amidst corrosive saltwater, high winds, and unpredictable sea states. This unique environment demands an extraordinary combination of structural resilience, precise motion control, and operational flexibility. This technical article delves into the engineering principles, key advancements, and critical applications that define modern offshore crane technology, illustrating how innovation tackles the inherent challenges of the open sea.

Product Overview

This product is a hydraulic knuckle boom crane designed for the marine crane industry and is a Hot Product of 2025. It comes with a 1-year warranty for the whole machine, while the core components (engine, bearing, gearbox, motor, gear, pump) are covered by a 1.5-year warranty. The crane has a lifting capacity of 1–20 tons, is constructed from Q235 material, and features 360-degree hydraulic slewing. It is equipped with a hydraulic knuckle boom, a remote radio control system, and is powered by a hydraulic system. The exterior color can be customized according to customer requirements. Designed with the typical structure of a marine knuckle boom crane, it is suitable for various vessels and offshore operations.

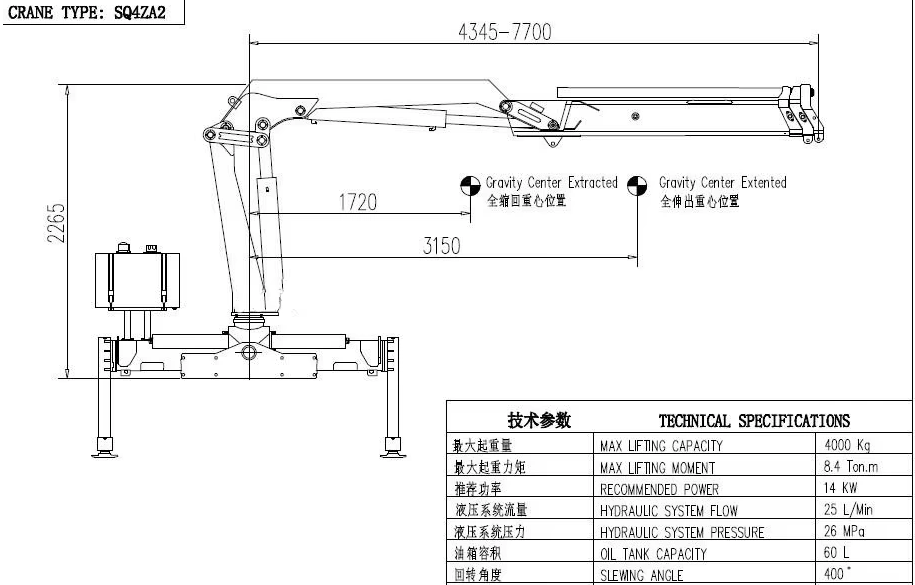

This marine crane has a maximum lifting capacity of 4 tons (4000 kg) with a corresponding maximum lifting moment of 8.4 ton·m. It is powered by a recommended 14 kW system and operates using a hydraulic system with a flow rate of 25 L/min and a working pressure of 26 MPa. The hydraulic oil tank has a capacity of 60 L. The crane offers a slewing angle of 400°, has a self-weight of 1250 kg, and requires an installation space of 850 mm.

Confronting the Core Challenge: The Dynamic Marine Environment

The fundamental technical hurdle for any offshore crane is compensating for vessel motion. The six degrees of freedom in a seaway—particularly roll, pitch, and heave—induce complex pendulum-like swinging in suspended loads. This poses significant risks:

Safety Hazards: Uncontrolled swings can lead to collisions, deck impacts, or parted loads during critical phases like landing on a supply vessel or offshore platform.

Operational Inefficiency: Excessive load oscillation drastically reduces precision, slowing down operations and increasing the weather window required for work.

Structural Stress: Dynamic loads from a swinging payload impose higher stresses on the crane structure and the vessel itself.

Core Technological Innovations in Modern Offshore Cranes

Corrosion Resistance: Constructed from high-strength, low-alloy (HSLA) steels with specialized paint systems (often epoxy-based) and sacrificial anodes or impressed current cathodic protection to combat saltwater corrosion, ensuring long service life.

Robust Configuration: The primary structure typically consists of a welded base column (fixed to the deck), a rotating tower or slewing column housing machinery, and a boom. Boom options—Telescopic for variable reach, Knuckle-boom for superior maneuverability in confined spaces, and Fixed for simplicity—offer tailored solutions for different tasks.

Modular Power Systems: Modern designs offer flexible integration of Hydraulic Power Units (HPUs) or all-electric winch drives. This modularity allows the power pack to be mounted on the crane or remotely below deck, optimizing deck space and facilitating maintenance

Robust Construction: Welded steel plate structure with a rigid base column, slewing tower, and a durable truss or box-type boom.

Precise Motion Systems: Independent, high-torque hoisting, luffing, and slewing systems, all equipped with fail-safe brakes for secure operation.

Comprehensive Safety: Full compliance with international maritime and safety regulations, underscored by integrated overload protection and system monitoring.

Key Subsystems & Functional Mechanisms

Three primary mechanical systems enable full 3D load positioning:

Hoisting System: Comprises an electric or hydraulic motor, gearbox, drum, and wire rope. It features redundant braking systems (mechanical holding brakes and dynamic braking) for secure load handling.

Luffing System: Alters the boom angle to change the working radius. This can be achieved via hydraulic cylinders (for knuckle booms) or a wire rope and winch system.

Slewing System: Rotates the crane's upper structure (tower and boom) around the base column. It consists of a slewing ring (large bearing) driven by a pinion gear connected to a motor and gearbox.

These systems are powered by either an electro-hydraulic system (pumps, valves, actuators) or a fully electric drive system using variable frequency drives (VFDs) for smooth control and energy efficiency.

Evolution & Future Trends

The technology continues to evolve from traditional derrick systems to highly automated cranes.

Electrification & Sustainability: A clear trend toward all-electric cranes, eliminating hydraulic oil leaks and reducing CO2 emissions and noise pollution, aligning with stricter environmental regulations.

Increased Automation & Digitalization: Integration of AI for predictive motion compensation, remote monitoring via IoT (Internet of Things) sensors, and semi-automated lift sequences to enhance safety and efficiency.

Higher Capacities for Mega-Projects: The growth of offshore wind, particularly floating wind farms, drives demand for cranes with greater lift capacity, outreach, and sophisticated active heave compensation systems.

Conclusion

The modern offshore crane is a testament to advanced mechanical, marine, and control engineering. It is no longer merely a lifting device but a complex, integrated system designed to operate reliably at the frontier of harsh environments. By combining robust corrosion-resistant construction, intelligent motion-compensated control, and flexible modular designs, these cranes enable the safe and efficient execution of critical offshore operations. As maritime industries push further into deeper waters and undertake larger-scale projects, continuous innovation in offshore crane technology will remain fundamental to global energy, logistics, and maritime infrastructure.

HI! Partner

Henan Yuntian, as a contemporary manufacturing leader, has consistently focused on cutting-edge technology and development in the lifting equipment industry. We invite you to get in touch for professional services including customized crane selection, accurate pricing, and technical design drawings tailored to your needs.

GET A QUOTE

https://yuntiancrane.com/

sales@sgycranes.com

Phone:

+86-373-3055523

+86-17337353108