Key Advantages of Marine Hatch Cover Gantry Crane

1. Strong Lifting Performance

Dual Hoisting System: Uses two separate hoists. Each one controls two hooks (four hooks in total). This allows balanced and stable lifting of hatch covers.

High Capacity: Can lift loads from 3 to 40 tons. It can also be customized for heavier loads.

Precision Control: Offers smooth movement with anti-sway technology. This helps place loads accurately and safely.

2. Durable and Customizable Build

Adjustable Span and Height: Can be modified to match different shipyard layouts and ship sizes.

Strong Construction: Made with a heavy portal frame, reliable travel system, and reinforced hoisting system for long service life.

Corrosion Resistance: Has special coatings to resist seawater and other harsh marine conditions.

3. Improved Safety and Reliability

Stable Operation: Four-hook synchronized lifting prevents hatch covers from tilting or slipping.

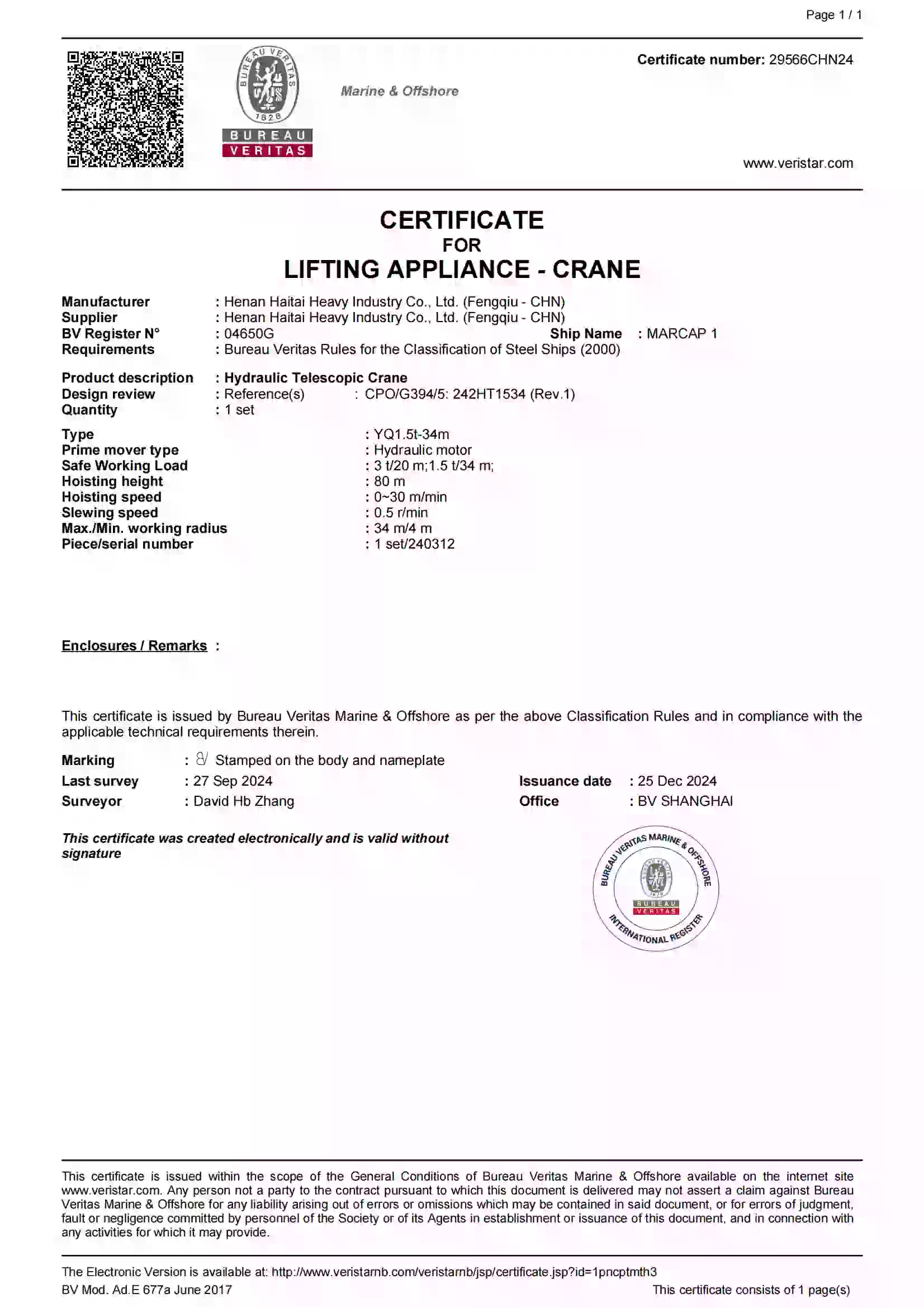

Meets Standards: Complies with international marine safety rules such as ISO and DNV.

Safety Mechanisms: Includes overload protection, emergency brakes, and secure locks.

4. Automation and Efficiency

Semi/Full Automation: Can work with smart control systems to reduce manual operation.

Fast Operation: Designed for quick removal and installation of hatch covers. This reduces ship waiting time.

Multiple Uses: Suitable for loading, unloading, maintenance, ballast operations, and emergencies.

A marine crane is a special type of crane used in ocean environments. It is mainly used for moving goods between ships, sea supply, and handling underwater equipment. The marine environment makes crane control difficult. On one hand, like land cranes, it must control load swing to ensure accurate positioning and efficient movement. On the other hand, because the crane is fixed on a moving ship, the ship’s motion greatly affects the load.

It consists of a derrick, mast, ropes, and winch. The derrick system is a traditional ship loading equipment. It has many ropes and is complex to operate, but it is still widely used because it is simple, cheap, and reliable.

Key Features

High loading and unloading efficiency

High operating speed

Small deck space needed

Suitable for heavy loads

A marine crane, also known as a ship crane, is installed on a vessel. It is used for loading goods, lifting items, and maintaining ship equipment.

Cargo Handling: It can efficiently and safely lift and move different types of cargo, such as containers, bulk goods, and heavy items. This improves loading and unloading speed.

Equipment Maintenance: It can be used to lift and repair ship equipment during voyages.

Common Types

By Structure:

Slewing Cranes: Can rotate horizontally for a wider working range.

Fixed Cranes: Mounted in one place, suitable for specific areas.

By Lifting Capacity:

Light-duty, medium-duty, and heavy-duty cranes. They meet different ship and operational needs.

Lifting Capacity: Key measure of performance (in tons), ranging from a few tons to hundreds of tons.

Working Radius: Effective operating distance.

Flow Rate: Amount of liquid output per unit of time, reflects work efficiency.

Lifting Speed: How fast the crane can lift goods.

Rotation Speed: Affects operating efficiency and flexibility.

Gear Pump: Simple structure, low cost, reliable operation, but has large pressure and flow changes.

Cargo Ships: Widely used on bulk carriers, container ships, etc. Essential for loading and unloading.

Workboats: Such as salvage ships and dredgers. Used to lift equipment and materials.

Hatch Cover Opening/Closing System: Used to open and close hatch covers.

Offshore Platform Supply Vessels: Provide lifting services for offshore platforms.

Regular Inspection: Check wear of mechanical parts, lubrication, and electrical connections.

Cleaning: Remove dirt and debris to avoid corrosion and blockage.

Lubrication: Ensure key parts are well-lubricated to extend service life.

Safety Checks: Test brakes, limit switches, and other safety parts to ensure safe operation.

Performance Parameters

Application Areas

Maintenance

As important equipment on ships, marine cranes must work reliably. Good performance is essential for efficiency and safety. Regular maintenance and proper operation help serve marine operations better.

Versatile Applications

Shipyards & Dry Docks: Perfect for hatch cover setup when building or repairing ships.

Ports & Terminals: Speeds up cargo loading and unloading on bulk carriers and container ships.

Offshore Platforms: Helps with hatch operations on supply vessels and floating storage units.

Why Choose Our Hatch Cover Gantry Crane?

✔ Long Lifespan: Built for tough conditions and heavy use.

✔ Saves Money: Lowers labor costs and avoids delays with faster handling.

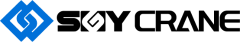

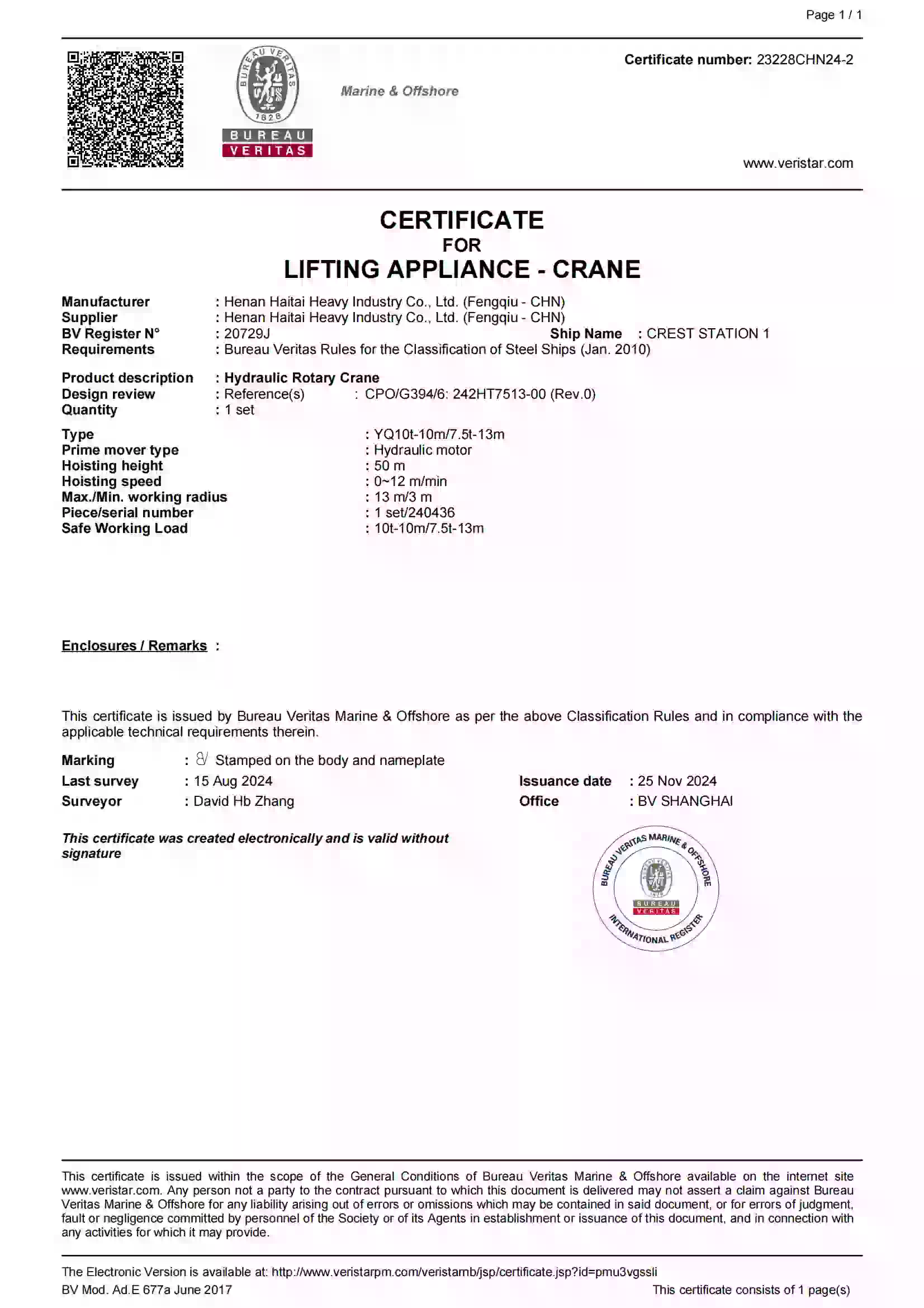

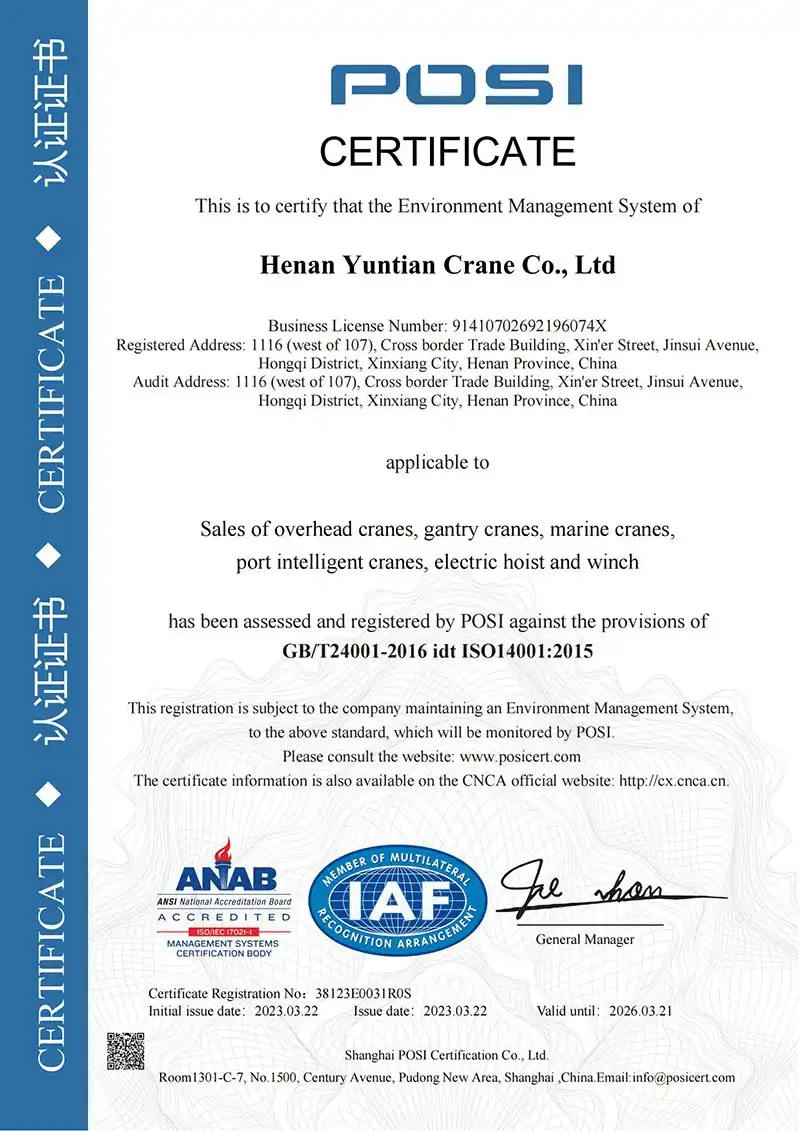

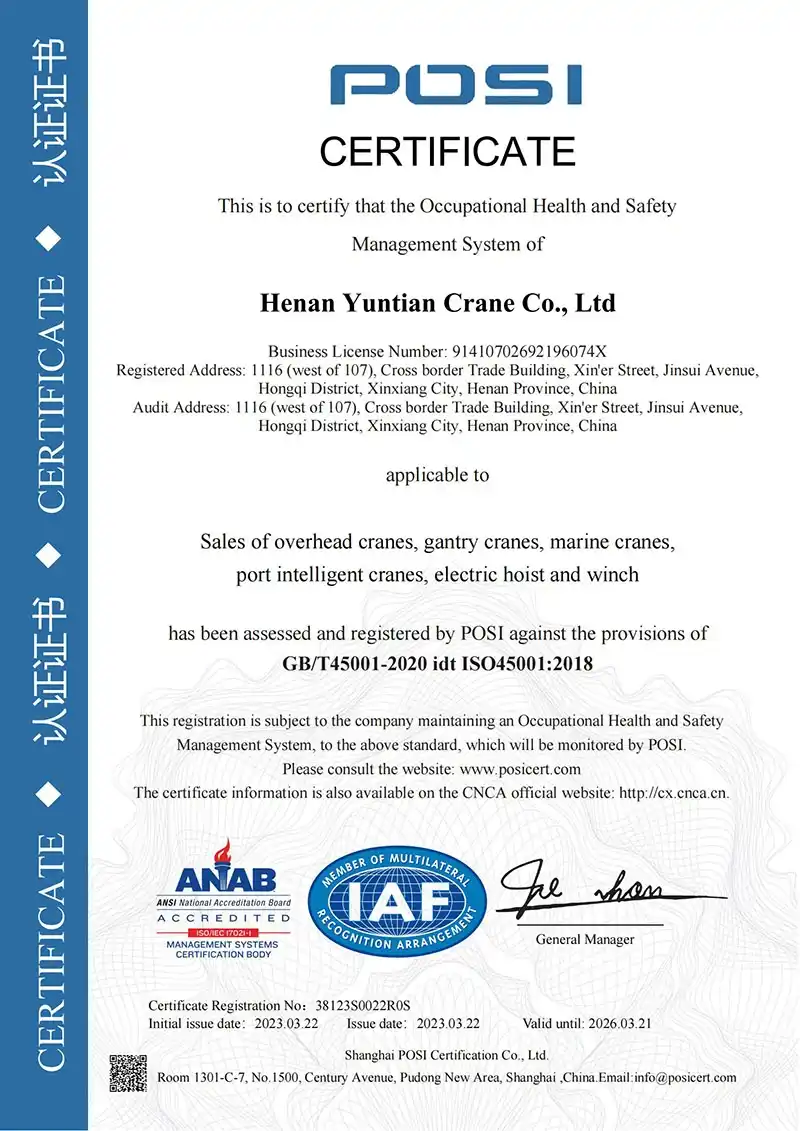

✔ Meets Global Standards: Certified for safety and performance in marine use.

✔ Custom Builds: We adjust span, height, and capacity to fit your needs.

Marine lifting equipment is essential for offshore operations. Its safety and reliability affect both crew and vessel safety. So, strict inspection is very important. It ensures safety and efficiency during marine operations.

Inspections include checking the structure, testing performance, and verifying safety devices. These steps help find and fix safety risks early. They keep the equipment working well and extend its service life. Operators must also follow operating rules closely to ensure safety.

Here is a real example from an inspection:

On October 14, 2024, during a routine check on oil tanker A at Hengli Petrochemical Port, Dalian Changxing Island Maritime Authority found 8 defects. One was especially notable: the ship’s lifting equipment did not have valid inspection certificates.

Defect details:

– Two lifting devices at midship and stern lack valid inspection certificates. (Must be fixed before departure.)

Relevant Rules:

According to Chinese domestic ship inspection rules (2020), all lifting devices must follow specific technical standards. The 1999 rules state that all ship lifting equipment must undergo official inspection. Certificates require initial, annual, and renewal inspections. Equipment must also be marked with safe working load, test date, ID number, and inspection agency.

The ship was built in 2010, so it must follow the 1999 rules. During inspection, the captain could not provide valid certificates. The ship company mistakenly thought small lifting devices did not need certification. After explanation by inspectors, the ship contacted the inspection agency. The ship was allowed to proceed without using the cranes until next repair, when they must be inspected and certified.

Points for Attention When Using Ship Cranes:

Before use, check the ship’s tilt. Ordinary transverse tilt should not exceed 5°, longitudinal tilt not over 2°. Wind speed should be below 20m/s. Confirm fuel and oil temperature are normal. Check that wire ropes are in good condition and winch pulleys work properly. After use, lock the boom and hook. Check pumps and motors for oil leaks.

Operators must know how to control the crane and handle emergencies. Unauthorized personnel should not enter the operating area or come near the crane during work.

Ships should regularly check wire ropes and hooks. Change hydraulic oil regularly. Keep key parts well-lubricated. Perform annual crane inspections.

Main Inspection Points and Common Defects:

Check if crane equipment is inspected on time. Initial inspection is required before use. Regular tests and inspections are required after. Additional inspection is needed after damage or repair.

Check if load indicators and limit switches work properly. Do not exceed safe load during operation.

Check wear and corrosion:

Look for deformation or cracks in metal structures.

Check for excessive wear or rust in wires.

Check brake pads and gears for wear or cracks.

Parts with over 10% corrosion or cracks should be replaced or repaired.

Wire ropes with serious corrosion or too many broken wires must be replaced.

Brake pads showing wear down to rivets must be replaced.

Cracked or broken gears must be replaced.

Check hydraulic pipelines. Make sure rotation systems and bearings work well with no oil leaks.

Common Defects:

Ship cranes not inspected as required.

Missing inspection record book or certificate.

Expired inspection record book or certificate.

Overloading beyond safe capacity.

Physical damage to cranes, wires, or moving parts.

Hydraulic oil leaks in cranes.

Tips for Using Hatch Covers:

Hatch covers protect cargo from bad weather and keep seawater out. But over time, they can rust or deform. Regular maintenance and careful use are important.

Always follow the manufacturer's instructions for operation, inspection, and maintenance.

Operators should receive training. A supervisor should watch when opening or closing covers.

Do not work on or place loads on covers unless sure they are closed and secure.

-

Do not use cloth to cover partially open hatches—it is dangerous.

For powered covers:

Keep crew away from the hatch area. Make sure no items block the cover.

Mind the ship’s trim. Do not remove locks or pins before securing brake cables.

Secure covers immediately after opening or closing. Do not climb on unsecured covers.

Keep pulleys lubricated and clean. Keep tracks and drains clear. Keep rubber seals in good condition.

When operating:

During voyage: Keep all locks and fasteners secured. Lubricate regularly. Inspect often.

-

Only authorized crew should operate electric hatch covers, except in emergencies.

For manual covers:

Keep enough covers and beams on board.

Use cranes or winches with enough strength to lift covers. Position crane directly above to reduce swinging. Only trained staff should operate under officer guidance.

-

Before moving covers, make sure everyone is clear of the area.

For manual handling:

Handle covers, beams, and tarps carefully. Store them safely.

Open covers from center to side. Close from side to center.

When using tarps, walk forward to see where you are going.

Position crane directly above when lifting beams.

Secure partly opened beams and covers to prevent movement.

Never walk on beams.

Do not use covers as work platforms or storage unless approved by an officer.