Key Advantages of Rail-Mounted Gantry Cranes (RMGs)

Superior Load Handling

RMGs handle heavy loads well. They can lift between 5 to 500 tons. They work with 20ft, 40ft, 45ft, and 53ft containers. This makes them suitable for both standard and oversized cargo in busy logistics hubs.

Better Space Use

RMGs run on fixed rails. They make good use of both vertical and horizontal space in the yard. They can stack containers 5-6 high and move precisely along rails. This allows more storage compared to rubber-tired cranes (RTGs). The U-shaped design offers up to 7 meters of clearance under the legs, which helps with handling large cargo.

Higher Productivity

RMGs use modern technology like vector frequency control and torque balance systems. These features save energy and increase handling speed. The rail-guided movement is smooth and steady. This reduces operation time in ports and intermodal yards. RMGs are built for high-intensity tasks (A5-A8 duty cycles).

Automation and Smart Systems

RMGs support manual, semi-automatic, and remote control modes. They include systems like CMS (Intelligent Service Management) and electronic anti-sway. These allow real-time monitoring, precise positioning, and less container shaking. This reduces mistakes and downtime.

Durability and Flexibility

RMGs are made for tough conditions. They work 24/7 in ports and extreme weather. They have weather-proof parts and strong steel structures. They are used in port terminals, railway yards, logistics centers, and industrial zones handling special project cargo like wind turbine parts.

Main Features

Customizable Design

RMGs can be customized. Options include cantilevered or non-cantilevered beams, double-girder designs, and upper/lower slewing mechanisms. This helps fit specific yard layouts and operational needs.

Safety Systems

RMGs include automatic fault detection, high wind alarms, and safety scanning. These features improve safety—especially important in busy industrial areas with heavy lifting.

Energy Saving

Optional energy recovery systems and grid power connection help lower energy costs. This supports green logistics.

Accuracy in Intermodal Handling

The rail system ensures precise positioning. This is essential when moving double-stack containers between trains, trucks, and ships.

RMG cranes are efficient, stable, and smart. They are well-suited for container handling along railway lines. They improve loading and unloading efficiency and reduce labor costs.

Currently, most automated container terminals use a layout where the yard is perpendicular to the quay. Each container block uses two RMGs. These two RMGs work together to move containers in and out of the block. Interactions between internal and external containers happen at both ends. The two RMGs run on the same track and are identical. One handles the land-side operations and the other the sea-side.

In this process, RMGs must carry containers while moving. This leads to lower efficiency and higher energy use. Also, the two RMGs cannot cross each other’s path, which limits flexibility in container storage and retrieval.

To solve this, a cross-over dual RMG model has been proposed (also called Nested RMG or Double-rail-mounted gantry crane). In this system, the two Automated RMGs (ARMG) in one block can cross each other’s path. Each ARMG can cover the entire block, offering greater flexibility. The CTA container terminal in Hamburg, Germany, once used this type of ARMG and operation method.

Some experts have also studied its use in intermodal train container yards. Research shows that in such environments, cross-over RMGs do not always provide a clear advantage over non-cross-over RMGs. This is because RMGs mainly move vertically. Interference caused by non-crossing can be avoided through optimized operation planning.

In recent years, many ports have upgraded or built new container terminals to meet growing container transport demand. They are adopting RMG-based yard operations that allow high-density storage and support advanced technology.

Benefits of this system include:

Better yard space utilization

Relatively simple mechanical structure

Easy maintenance

Reliable operation

Electric power, which saves energy and reduces pollution

Computer control support, making automation easier

A rail-mounted gantry crane (often called RMG) is a type of specialized equipment used in container yards. It uses grid electricity and moves on rails. It is equipped with a 20' or 40' telescopic spreader (and sometimes a twin-lift spreader). It lifts and stacks containers within a defined area.

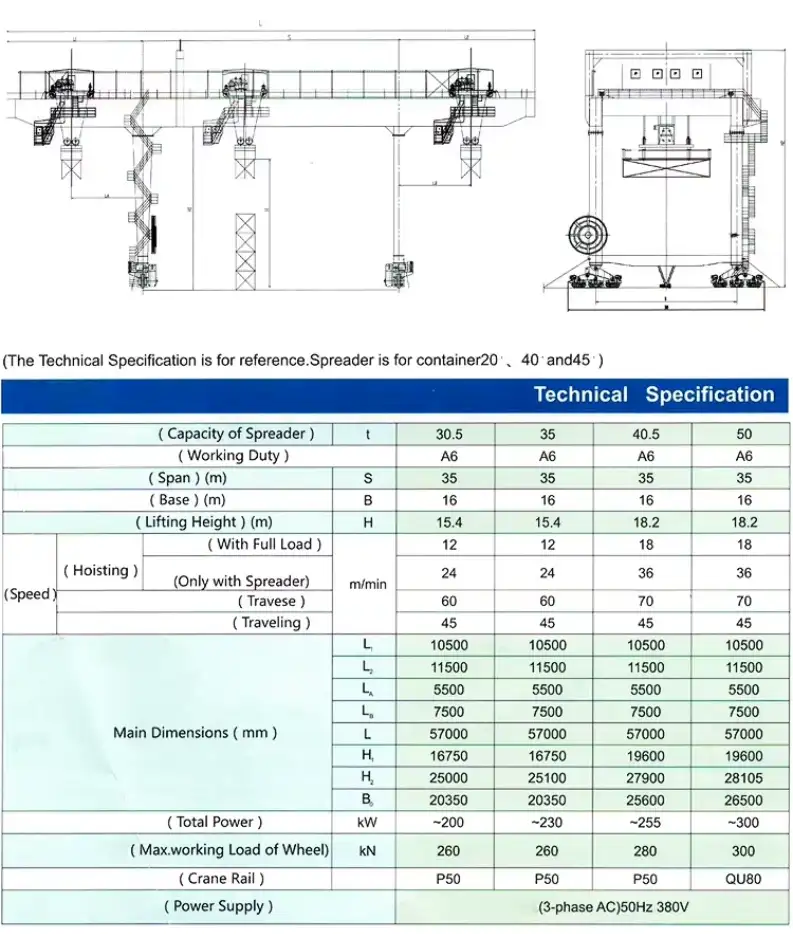

Typical RMG parameters include:

Gauge: 23 m

Rated load under spreader: 40 t

Loaded hoisting speed: 23–30 m/min

Unloaded hoisting speed: 46–60 m/min

Trolley travel speed: 63–70 m/min

Gantry travel speed: 50–120 m/min

Can include cantilevers or not

Main mechanisms include hoisting, trolley travel, gantry travel, and anti-sway. Most use AC frequency control. The hoisting mechanism is usually a single-drum type, but a double-drum type is also available.

RMG stands for rail-mounted gantry crane. It uses steel wheels running on tracks.

Automated RMGs used in port inland container yards are efficient, stable, and reliable. Automation systems can partly or fully replace manual work in repeated container handling tasks. Using automation improves terminal efficiency, shortens ship turnaround time, increases port throughput, and reduces labor costs. It also supports the trend toward larger and faster container ships.

RMG is the most common type of automated container yard crane worldwide. Its automation systems are more advanced and comprehensive than those of RTGs.

RMG automation systems include:

Public Address (PA) System

When a truck enters the dedicated lane near the RMG, the PA system uses voice guidance to help the driver reach the exact parking position. It says “move forward,” “stop,” or “move back” as needed.Chassis Lift Protection System (CLPS)

Prevents the RMG from lifting a container together with the truck if the lock is not released. If the truck is lifted more than 1 meter, the RMG stops.-

Chassis Alignment System (CAS)

Scans the truck’s position and type (single or double layer). Works with traffic lights to guide the driver to the correct spot. Container Number Recognition System (CNRS)

Uses cameras to capture container numbers and converts them into digital data. This information is sent to the control and yard management systems.Final Landing System (FLS)

Uses cameras or lasers on the spreader to align the container. Helps avoid skewed landing.-

Crane Video Management System (CVMS)

Manages all cameras on the RMG. Provides real-time monitoring of the yard, lanes, and other cranes. Feed is sent to the central control room. Remote Vision System / Network Video Recorder (RVS / NVR)

Provides video monitoring and recording. Can compare real-time images with preset references to check operation status.Spreader Position Control System (SPCS)

Uses scanners to detect the spreader and container position. Adjusts skew to ensure precise handling.Spreader Profile Scanning System (SPSS)

Scans container stack height and detects potential collisions with stored containers. Stops operation if risk is detected.Prime Mover Number Recognition System (PMNRS)

Uses RFID to read truck identification tags. Records truck information for operation tracking.

Fully automated RMGs operate without human drivers. They greatly improve efficiency and reduce ship waiting time. This increases port throughput and brings significant economic benefits.

Today, individual automated systems are integrated into one or more electrical control units. Automated RMGs use RFID, infrared sensors, laser scanning, imaging, and video recognition—all connected via network communication—to enable smart sensing, scanning, identification, positioning, and monitoring.

For example, the PSA Pasir Panjang Terminal in Singapore uses automated RMGs with these systems.

Application Scenarios of Rail-Mounted Gantry Cranes (RMGs)

Port Container Terminals

RMGs are key equipment in port logistics. They load and unload containers between ships, trucks, and trains. RMGs stack containers 5-6 high and move precisely on rails. This saves space in busy ports and reduces ship waiting time. They work 24/7 in tough coastal conditions. Ports like Rotterdam and Singapore use RMGs widely.

Intermodal Rail Yards

RMGs move containers between trains and trucks. The rail system helps position containers accurately. This is important for moving freight across different transport types. RMGs are essential in hubs that connect rail and road networks.

Large Container Storage Yards

RMGs handle frequent operations (A5-A8 duty cycles). They organize and stack containers in big storage yards. Their span ranges from 18 to 35 meters. They use vertical space well to save land. Containers can be accessed quickly.

Railway Freight Terminals

RMGs are built for railway work. They load and unload containers from trains. The U-shaped design gives up to 7 meters of clearance under the legs. This fits train cars well. RMGs are strong and reliable for heavy rail tasks.

Logistics and Distribution Centers

In freight hubs, RMGs help sort, store, and move containers. They work with 20ft to 53ft containers. They connect to smart terminal systems (STS). This keeps workflow smooth in large logistics networks. It reduces delays in supply chains.

Special Industrial Areas

RMGs also handle heavy and oversized loads. Examples include wind turbine parts and offshore containers. Spans and load capacity (up to 500 tons) can be customized. This meets special needs in energy and heavy industry projects.

The Xiamen Yuanhai Automated Terminal in Fujian is China’s first automated terminal. It uses automated cranes. The Tianjin Port also uses automated cranes.

The Qingdao Automated Container Terminal in Shandong is Asia’s first full automated terminal. In its first 7 hours of operation, 12 yard cranes worked together. They loaded 854 containers. The average rate was 22 moves per hour. The error rate was only 3%. This greatly improved efficiency and capacity. It brought much higher economic benefits than manual cranes. It helps the port handle large container ships.

The Yangshan Phase IV Automated Terminal in Shanghai is the world’s most advanced automated terminal. It is also the largest single fully automated terminal. It started trial operation. It fully automates loading and unloading from ships and moving containers in the yard. No workers are on the cranes. It operates 24 hours non-stop. The handling rate reaches 40 moves per hour. This is much higher than manual terminals.

The project team follows strict procedures. They protect finished parts well. They plan storage locations based on ship plans. They use professional tools to secure parts during moves. This improves stability.

Workers check part information carefully. They control every detail. Each package unit has clear labels. Color tags help identify four product sets. This supports easy recognition and management.

The team works with experienced logistics partners. They prepare fully for shipping.

The new Rail-Mounted Gantry (RMG) is a highly compatible pre-automated machine. It meets various needs in intermodal or container terminal operations. It can be customized for new ports or existing terminals. It works with horizontal transport or mobile equipment. This offers full terminal solutions for intermodal and container terminals.

All RMGs use electric drives. This improves efficiency. Operation is smooth with zero emissions.

RMGs have a rail span of 20-25 meters. They lift up to 65 tons. Lifting height reaches 18 meters. They can stack 6+1 containers.

Rail-Mounted Gantry (RMG) cranes are used in container terminals and yards. They handle loading, unloading, moving, and stacking containers.

RMGs use electric power. They save energy, protect the environment, and cost less. They break down less often. They are the first choice for new terminals now and in the future.

RMGs are usually larger than rubber-tired gantry cranes (RTGs). They stack higher. RMGs run on fixed tracks.

RMGs have strong positioning ability. They are easy to automate fully. They are ideal for automated container terminals.

RMGs move containers between the yard and the quay. They can work at night efficiently by remote control.

Compared to traditional straddle carriers or RTGs, RMGs stack containers more closely. This improves yard space usage greatly.