In the demanding world of maritime and offshore operations, efficiency, safety, and adaptability are non-negotiable. When it comes to lifting and handling cargo, supplies, or equipment on vessels and platforms, one piece of equipment stands out for its ingenious design and unparalleled versatility: the Marine Knuckle Boom Crane.

More than just a crane, this powerful system is a linchpin for logistics, construction, and survival at sea. This comprehensive guide delves into what makes the marine knuckle boom crane an indispensable asset for the global maritime industry.

What is a Marine Knuckle Boom Crane?

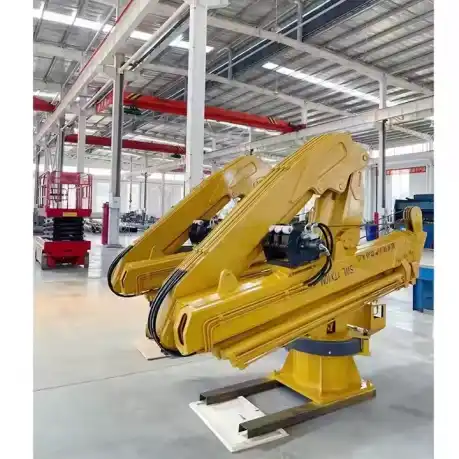

A marine knuckle boom crane, often referred to as an articulating crane or a "foldable knuckle crane," is a hydraulic crane with a boom that consists of two or more articulating sections connected by pivot points (the "knuckles"). This design allows the boom to fold in on itself, much like a human finger, enabling complex movements that are impossible for straight boom (telescopic) cranes.

Key components include:

Base Column:The fixed mounting point, often with a continuous 360-degree rotation (slewing) capability.

Main Boom:The first and primary section attached to the column.

Knuckle Boom (Fly Jib):The second articulating section, connected to the main boom.

Hydraulic Actuators:Powerful cylinders that control the extension, retraction, and folding of the boom sections.

Hook Block or Grapple:The end attachment for lifting loads.

Key Advantages Over Traditional Telescopic Cranes

Why has the knuckle boom design become the gold standard for many marine applications?

Exceptional Versatility and Reach:The articulating arm can reach over, under, and around obstacles—like vessel superstructures, containers, or railings—to place loads with pinpoint accuracy. It can operate effectively in confined spaces where a straight boom would be useless.

Compact Stowed Position:When not in use, the crane folds into a remarkably small footprint. This is critical for vessel stability, deck space optimization, and reducing air draft for passing under bridges.

Superior Control and Precision:The multiple points of articulation allow operators to maneuver loads with a high degree of control, enabling delicate placements essential for sensitive equipment or operations in close proximity to other assets.

Multi-Functionality with Attachments:Beyond a standard hook, these cranes can be fitted with various hydraulic tools like grapples, winches, personnel baskets (man-riding), augers, or even demolition shears, transforming them into multi-purpose workstations.

Enhanced Safety:The ability to control the load path more precisely reduces swinging, a major hazard at sea. Their stability and often higher safety factors make them suitable for the dynamic marine environment.

Primary Applications in the Maritime Sector

The marine knuckle boom crane is a workhorse across numerous offshore and maritime segments:

Offshore Support Vessels (OSV):For handling cargo, containers, and supplies between vessels and offshore oil & gas platforms (platform supply operations).

Wind Farm Installation & Service Vessels:Critical for transferring technicians, tools, and spare parts to wind turbines. Man-riding capabilities are often certified for these cranes.

Cable-Laying & Research Vessels:Handling sensitive equipment, ROVs (Remotely Operated Vehicles), and deep-sea sampling devices with care.

Fishing & Processing Vessels:Used for handling nets, cages, and processing equipment on factory trawlers.

General Cargo & Container Ships:For handling stores and cargo in ports where shore cranes are unavailable.

Naval & Coast Guard Vessels:Used for logistics, replenishment at sea, and launch/recovery of small boats.

Choosing the Right Marine Knuckle Boom Crane: Key Considerations

Selecting a crane requires a careful analysis of operational needs:

Lifting Capacity (& Load Chart):Determine the maximum weight you need to lift, not just at maximum reach, but throughout the working radius. Marine cranes are rated for dynamic conditions (moving vessel).

Maximum Reach & Working Radius:How far horizontally and vertically must the crane reach? Consider both stowed and operational dimensions.

Sea State & Dynamic Factors:he crane must be certified (e.g., DNV, ABS, Lloyd's Register) for specific sea states (e.g., Heave Compensation may be required for heavy lifts in rough seas).

Control System:Modern cranes offer proportional radio remote controls and cabin-operated systems with intuitive joysticks and safety overload systems.

Corrosion Protection:Given the harsh saltwater environment, a robust protective coating (epoxy, zinc) and use of corrosion-resistant materials like stainless steel for critical components are essential.

Conclusion: The Smart Investment for Modern Marine Operations

The marine knuckle boom crane is not merely a tool; it is a strategic investment that enhances operational capability, safety, and profitability. Its unique blend of compact storage, expansive reach, and precise control solves the complex logistical challenges posed by the ocean.

For any vessel operator or offshore project manager looking to optimize deck space, streamline cargo operations, and equip their asset with a reliable, multi-functional lifting solution, specifying a high-quality **marine knuckle boom crane** is a decisive step toward achieving those goals.

Ready to specify your marine lifting solution?Consult with a certified marine crane manufacturer to review your vessel's plans and operational profile for a tailored recommendation.

HI! Partner

Henan Yuntian, as a contemporary manufacturing leader, has consistently focused on cutting-edge technology and development in the lifting equipment industry. We invite you to get in touch for professional services including customized crane selection, accurate pricing, and technical design drawings tailored to your needs.

GET A QUOTE

https://yuntiancrane.com/

sales@sgycranes.com

Phone:

+86-373-3055523

+86-17337353108