Abstract: The Rail Mounted Container Gantry Crane (RMG) stands as a critical piece of capital-intensive equipment at the heart of modern, high-throughput container terminals and intermodal rail yards. This research-oriented article provides a comprehensive examination of RMG technology, delving into its design principles, operational advantages, key technical specifications, and its pivotal role in optimizing land use and logistics efficiency. By analyzing its integration within automated terminal operating systems and contrasting it with alternative solutions like Rubber-Tired Gantry Cranes (RTGs), this paper aims to offer terminal operators, port planners, and logistics engineers a detailed understanding of RMG systems' strategic value.

1. Introduction: Defining the Rail Mounted Container Gantry Crane

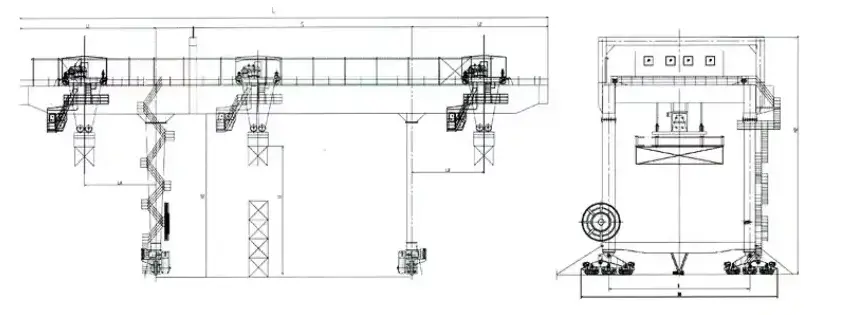

A Rail Mounted Container Gantry Crane (RMG), also known as a Rail-Mounted Gantry (RMG) crane, is a large, cantilevered or non-cantilevered crane designed for the stacking, loading, and unloading of ISO shipping containers. Its primary distinguishing feature is that it moves on fixed, dedicated rail tracks, unlike its counterpart, the Rubber-Tired Gantry Crane (RTG), which operates on a paved yard surface. RMGs are predominantly employed in container storage yards, where they service container blocks between transfer points (like truck lanes or automated guided vehicle [AGV] zones) and the stacking area, and are also fundamental in intermodal rail terminals for loading/unloading trains.

2. Historical Evolution and Design Philosophy

Te development of the RMG is a direct response to the exponential growth in global containerized trade and the consequent need for higher density, faster turnaround, and more predictable container handling. Early container yards relied on slower, less precise equipment. The RMG evolved from traditional bridge cranes, adapted for the massive scale and outdoor environment of ports. Its design philosophy centers on:

High Density: Maximizing vertical stacking (often 1-over-6 or higher) and minimizing aisle width between container rows.

Precision and Repeatability: Fixed rails provide a highly predictable and accurate movement path, which is essential for automation.

Lift Capacity and Span: Engineered to handle containers ranging from 20ft to 53ft, with spans wide enough to cover multiple container rows and a truck/rail lane.

3. Core Technical Components and Specifications

A modern RMG is an engineering marvel consisting of several key subsystems:

Portal Frame & Legs: The main steel structure that spans the container block. It travels on wheels along parallel ground-level rails.

Hoisting Trolley: Moves transversely across the bridge girder(s), carrying the spreader. It houses the main hoist machinery.

Spreader: A telescopic twistlock mechanism that engages with the container's corner castings. Modern spreaders are highly automated, capable of handling multiple container sizes and detecting container presence.

Drive System: Electric motors power the gantry's long travel (along the rails) and the trolley's cross travel. Regenerative braking is increasingly standard.

Power Supply: Typically fed by conductor rails (sliding shoe collectors) or cable reels, facilitating continuous operation.

Control & Safety Systems: Include programmable logic controllers (PLCs), anti-sway systems, collision avoidance, and sophisticated human-machine interfaces (HMIs) or fully automated control stations.

Key Specifications include lifting capacity (typically 40-50+ metric tons under the spreader), stacking height, span width (covering 6+1 or 8+1 container rows and a lane), and operating speed (hoisting, trolley, and gantry travel).

4. Operational Advantages and Efficiency Metrics

RMGs offer distinct operational benefits that translate into tangible business value:

Superior Stacking Density: Fixed rails allow for narrower operating aisles, increasing storage capacity by up to 30% compared to RTG-operated yards.

Higher Productivity & Predictability: Smooth, rail-guided motion enables faster and more precise container positioning, leading to more moves per hour (MPH) with less cycle time variability.

Reduced Maintenance & Ground Damage: Running on steel rails eliminates tire costs and wear associated with RTGs. It also prevents rutting and damage to the yard surface.

Improved Energy Efficiency: Electric power from the grid is more efficient and cleaner than diesel generators used in traditional RTGs. Regenerative drives feed energy back into the system during lowering and braking.

Enhanced Safety: The fixed travel path significantly reduces the risk of collisions with other mobile equipment or personnel in the yard.

5. RMGs vs. RTGs: A Comparative Analysis

The choice between RMG and RTG is a strategic decision. RTGs offer flexibility in yard layout and are often preferred in smaller or multi-purpose terminals. However, for large-scale, dedicated container operations, RMGs are generally superior:

Cost: Higher initial CAPEX for RMGs (including rail infrastructure) is offset by lower long-term OPEX (energy, maintenance).

Automation: RMGs are inherently more suitable for full automation due to their fixed path and positional accuracy.

Flexibility vs. Stability: RTGs can be redeployed; RMGs define a permanent, high-productivity yard layout.

6. Integration with Automation and Terminal Operating Systems (TOS)

The true potential of RMGs is unlocked through automation. They are the workhorses of semi-automated and fully automated container terminals.

Automated RMGs (ARMG): Operate without an onboard driver, controlled remotely from a central control room or automatically by the TOS.

TOS Integration: The TOS sends work instructions (container pick-up and set-down coordinates) directly to the RMG's control system. The crane executes these moves autonomously, reporting status back in real-time.

Equipment Interfacing: Automated RMGs seamlessly interact with other automated equipment like AGVs, automated straddle carriers, or container handling robots, creating a synchronized, continuous-flow logistics chain.

7. Challenges and Considerations in Deployment

Deploying an RMG system is not without challenges:

High Initial Investment: Significant capital is required for the cranes, rail infrastructure, and electrical substations.

Infrastructure Rigidity: The layout is fixed; future expansion or reconfiguration requires major construction.

Technical Complexity: Requires skilled personnel for maintenance and programming, especially in automated setups.

Single Point of Failure: A breakdown on one crane can potentially block an entire block. Redundancy and maintenance planning are critical.

8. Future Trends: Electrification, AI, and Smart Port Integration

The future of RMG technology is focused on intelligence, sustainability, and connectivity:

Full Electrification & Green Ports: RMGs are central to ports' decarbonization goals, moving away from fossil fuels entirely.

Artificial Intelligence (AI) & Machine Learning: AI algorithms will optimize stacking strategies (predictive stacking), maintenance schedules (predictive maintenance), and real-time path planning to avoid bottlenecks.

Digital Twins & IoT: Creating virtual models of RMGs fed by IoT sensors allows for simulation, performance monitoring, and remote diagnostics.

Enhanced Safety Systems: Integration of advanced computer vision and LiDAR for improved obstacle detection and operational safety in mixed manual/automated environments.

9. Conclusion

The Rail Mounted Container Gantry Crane is far more than just a lifting device; it is a strategic asset that defines the efficiency, capacity, and technological maturity of a modern intermodal terminal. Its superiority in stacking density, operational predictability, and suitability for automation makes it the undisputed choice for high-volume, capital-intensive logistics hubs aiming for long-term competitiveness. As global trade demands ever-greater efficiency and environmental stewardship, the evolution of the RMG—through AI, full electrification, and deep digital integration—will continue to be a cornerstone of the "Smart Port" revolution, ensuring the seamless, sustainable flow of global commerce.

HI! Partner

Henan Yuntian, as a contemporary manufacturing leader, has consistently focused on cutting-edge technology and development in the lifting equipment industry. We invite you to get in touch for professional services including customized crane selection, accurate pricing, and technical design drawings tailored to your needs.

GET A QUOTE

https://yuntiancrane.com/

sales@sgycranes.com

Phone:

+86-373-3055523

+86-17337353108