What is a Rubber Tyre Gantry Crane (RTG Crane)?

A Rubber Tyre Gantry Crane (RTG Crane), also known as a Rubber Tyred Gantry Crane, is a mobile gantry crane used primarily in port container terminals and intermodal yards for stacking shipping containers. Unlike its rail-bound counterparts, the defining feature of an RTG Crane is its ability to move freely on rubber tires, providing unparalleled mobility across the yard. A standard Rubber Tyre Container Gantry Crane can typically stack containers 1-over-5 or 1-over-6 high and span 6 to 8 container rows plus a working lane.

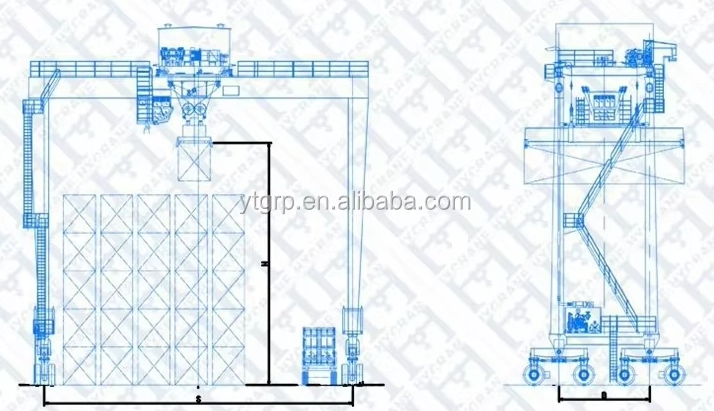

Rubber Tyre Container Gantry Crane (RTG Crane)

The Rubber Tyre Container Gantry Crane is the most common type found globally.

Main Components: The main structure consists of a tall, rigid steel frame (the gantry) that moves on multiple rubber tires. Key components include the legs, a single or double girder (main beam), a trolley that runs along the girder, a spreader (for lifting containers), and a powerful diesel engine or an electrical drive system (often via a cable reel or diesel-generator set).

Advantages & Features:

1.Great Mobility and Flexibility

Rubber tires allow the crane to move in all directions. It can go straight, sideways, turn between 0-90°, and even spin in place.

It does not need fixed rails. This makes it perfect for busy port yards, logistics centers, and intermodal terminals.

It works well even on uneven ground thanks to its strong tires.

2. Different Power Choices for Saving Energy

It can use a diesel generator to run on its own.

It can use hybrid systems with cable reels or lithium batteries. These save up to 30% fuel compared to older RTGs.

It can also use main electricity for zero emissions in powered terminals.

3. Better Safety and Automation

It uses PLC and AC frequency control for smooth and accurate movement.

An intelligent monitoring system (CMS) checks the equipment in real time.

Application Scenarios: The primary application for this RTG Crane is in port container terminals for stacking import/export containers, loading and unloading trucks, and transferring containers to and from straddle carriers or yard trucks.

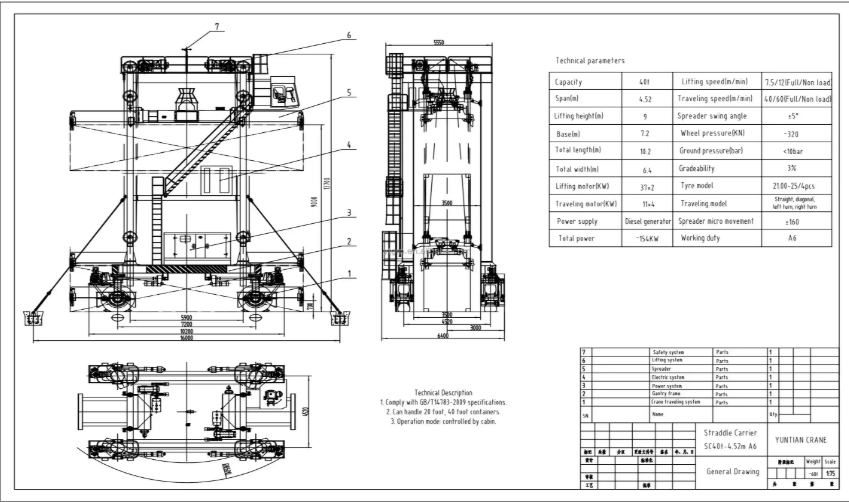

Straddle Carrier

While technically a different machine, the Straddle Carrier is a crucial piece of equipment that often works alongside the RTG Crane.

Main Components: It features a frame that "straddles" the container stack, equipped with a lifting spreader, and runs on large rubber tires. It has a dedicated cab for the operator.

Advantages & Features:

1. Strong Structure Design

Robust Main Beam: The U-frame is made as one solid piece without welding. Full-beam welding is used for high precision. This gives strong vertical and horizontal stiffness. It lowers the machine’s own weight, reduces wheel load, and improves stability.

Improved End Carriage: Uses a motor-reducer-wheel drive and soft-start motor. This allows smooth and steady movement, which reduces part wear.

Heat Resistant: A special heat-protection coating is applied under the main beam. This increases heat resistance and extends service life in high-temperature conditions.

2. High Performance and Efficiency

Long-Lasting and Efficient: Built for heavy, long-term use with very little downtime. It keeps working steadily in busy logistics areas.

Smooth and Reliable Operation: Starts and stops smoothly. The winch trolley runs quietly and does not gnaw the rail. This ensures stable performance.

3. High-Quality Parts and Safety Systems

Safe Tires and Spreader: High-quality rubber tires resist abrasion and have protection devices for flexible turning. The spreader uses four-leg wire rope slings to safely lock 20ft, 40ft, and 45ft containers.

Application Scenarios: Ideal for container yards with shorter transport distances, for directly loading and unloading rail cars, and for moving containers between terminal areas. It is a highly flexible alternative to the Rubber Tyre Gantry Crane.

Double Girder Tyre Gantry Crane

For heavy-duty applications beyond standard containers, the Double Girder Tyre Gantry Crane is the powerhouse.

Main Components: As the name implies, it has two main girders atop the leg structures, providing a robust platform. It features a more substantial trolley and hoisting mechanism, and can be equipped with a hook or a specialized spreader.

Advantages & Features:

1.Strong and Reliable Structure

Heavy-duty double girder design offers better load capacity and stability. It can lift up to 500 tons (can be customized).

Precision welding makes U-shaped beams very rigid. This reduces deformation and makes the crane last longer.

Better weight distribution lowers wheel pressure and improves safety.

2.Better Drive and Control

Smooth travel system uses soft-start motors and reducer-wheel drives. This prevents jerky movement.

Smart control uses Siemens or Schneider PLC systems with frequency conversion. This allows accurate speed control.

3.Suitable for All Environments

Special coating protects the main beam from high heat in steel mills or foundries.

Anti-corrosion materials make it good for ports or chemical plants.

Application Scenarios: Used in heavy industrial yards, steel mills, bulk cargo terminals, and large project cargo handling facilities where loads exceed the capacity of a standard Single Girder Rubber Tyre Crane.

Single Girber Rubber Tyre Crane

The Single Girber Rubber Tyre Crane is the economical and efficient choice for lighter-duty operations.

Main Components: This Rubber Tyre Crane features a single main girder connecting the legs, resulting in a lighter overall structure. It uses a simpler hoist and trolley system.

Advantages & Features:

1.Built to Standards and Reliable

Our crane is made according to GB/T 3811-2008, GB/T 14406-2011, and GB/T 14783. This means it meets strict national and industry standards for safety and performance.

2.Strong Structure

The main beam is formed in one piece without welding. This makes it lighter but also stronger in both vertical and horizontal directions.

Smaller wheel loads reduce ground pressure. This makes it ideal for outdoor container yards.

3.Smooth Movement

The rubber tyre system allows the crane to turn 360° on the ground. It works well in tight spaces like busy ports, rail yards, and intermodal areas.

Soft-start motors provide smooth acceleration. This reduces stress on the machine and prevents load sway.

Application Scenarios: Perfect for smaller container yards, warehouse loading bays, freight stations, and manufacturing plants for handling lighter containers, packaged goods, and general cargo.

HI! Partner

Henan Yuntian, as a contemporary manufacturing leader, has consistently focused on cutting-edge technology and development in the lifting equipment industry. We invite you to get in touch for professional services including customized crane selection, accurate pricing, and technical design drawings tailored to your needs.

GET A QUOTE

sales@sgycranes.com

Phone:

+86-373-3055523

+86-17337353108